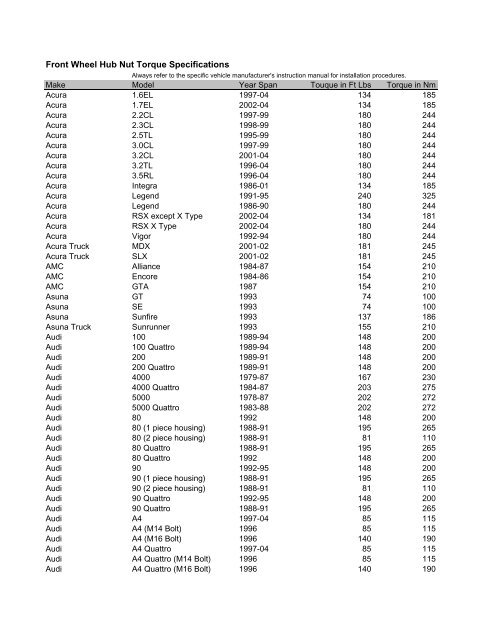

The wheel bearing torque specifications vary depending on the make and model of the vehicle. It is important to refer to the manufacturer’s guidelines for the specific torque requirements.

Wheel bearing torque specifications helps to ensure proper installation and performance of the wheel bearings. When installing or replacing wheel bearings, it is essential to adhere to the manufacturer’s recommended torque settings to prevent over-tightening or under-tightening, which can lead to premature wear or damage.

Proper torque specifications also help to ensure the safety and stability of the vehicle while in operation. By following the correct torque specifications, you can prolong the lifespan of the wheel bearings and maintain optimal performance, contributing to a smoother and safer driving experience.

Contents

Why Torque Matters In Wheel Bearings

Wheel bearing torque specifications are crucial for ensuring proper functioning and longevity of wheel bearings. By following the specified torque values, you can prevent issues like excessive heat, premature wear, and potential wheel assembly failures. Maintaining the correct torque helps to distribute loads evenly and ensures optimal performance of the wheel bearings.

The Role Of Torque

When it comes to wheel bearings, torque plays a crucial role in ensuring proper functioning and performance. Torque refers to the amount of rotational force applied to tighten the wheel bearings onto the axle. It is important to understand the role of torque in wheel bearings to ensure the longevity and safety of your vehicle.

Consequences Of Incorrect Torque

Incorrect torque specifications can have serious consequences for wheel bearings. If the torque is too loose, it can lead to excessive play between the bearing and the axle, causing vibrations, noise, and premature wear. On the other hand, if the torque is too tight, it can lead to excessive friction, overheating, and potential damage to the bearing components. Therefore, it is crucial to adhere to the manufacturer’s recommended torque specifications.

Here are some potential consequences of incorrect torque:

- Uneven wear on the bearing surfaces

- Increased risk of bearing failure

- Excessive heat generation

- Reduced fuel efficiency

- Unstable and unsafe driving conditions

Proper Torque For Wheel Bearings

To ensure the proper torque for wheel bearings, it is essential to consult the vehicle manufacturer’s specifications. These specifications can typically be found in the vehicle’s owner’s manual or service manual. The torque specifications may vary depending on the make and model of the vehicle, as well as the specific wheel bearing design.

It is important to note that torque specifications are typically provided in pound-feet (lb-ft) or Newton-meters (Nm). Using a torque wrench calibrated in the appropriate unit of measurement is crucial for achieving accurate torque values.

Here is a general guideline for tightening wheel bearings:

- Hand-tighten the wheel bearing until it is snug.

- Use a torque wrench to tighten the bearing to the initial specified torque.

- Rotate the wheel a few times to ensure proper seating of the bearing.

- Finalize the torque by tightening the bearing to the specified final torque.

By following the manufacturer’s torque specifications and the proper tightening procedure, you can ensure optimal performance and longevity of your wheel bearings, promoting a smooth and safe driving experience.

Finding The Right Specifications

When it comes to ensuring the optimal performance and safety of your vehicle, it’s crucial to adhere to the correct wheel bearing torque specifications. This ensures that the components are properly secured and can withstand the forces encountered during operation.

1. Manufacturer’s Guidelines

Manufacturers provide specific torque specifications for their wheel bearings, which can be found in the vehicle’s service manual or maintenance guide. It’s essential to adhere to these guidelines to prevent over-tightening or under-tightening, which can lead to premature wear or failure.

2. Online Resources And Manuals

In addition to the manufacturer’s guidelines, there are numerous online resources and manuals that provide comprehensive torque specifications for a wide range of vehicle makes and models. Websites, forums, and online databases can be valuable sources of information for locating the correct torque specifications for your specific vehicle.

When referencing online resources, it’s important to prioritize reputable sources, such as official manufacturer websites or trusted automotive forums. These sources often provide detailed and accurate torque specifications, helping to ensure the proper maintenance and repair of your vehicle’s wheel bearings.

Step-by-step Torquing Process

The step-by-step torquing process is crucial when it comes to wheel bearing torque specifications. Following the correct process ensures that the wheel bearings are tightened to the manufacturer’s recommended torque settings, preventing potential damage to the bearings and wheels.

Tools You’ll Need

Before starting the wheel bearing torque process, gather the following tools:

- Socket wrench set

- Torque wrench

- Jack and jack stands

- Clean rags

- Wheel chocks

Detailed Procedure

Follow these steps carefully to ensure proper wheel bearing torqueing:

- Secure the vehicle on a flat surface using wheel chocks.

- Jack up the vehicle and place it securely on jack stands.

- Remove the wheel and access the wheel hub assembly.

- Locate the wheel bearing nut and loosen it using a socket wrench.

- Use a torque wrench to tighten the wheel bearing nut to the specified torque value.

Safety Checks Post-torqueing

After torqueing the wheel bearing, perform the following safety checks:

- Ensure the wheel spins freely without any unusual noises.

- Check for any signs of leaks or damage around the wheel hub.

- Reinstall the wheel and lower the vehicle from the jack stands.

- Test drive the vehicle at low speeds to verify the wheel bearing’s performance.

Credit: www.ford-trucks.com

Credit: m.youtube.com

Frequently Asked Questions

Here are some FAQs about the wheel bearing torque specifications –

What Is The Torque For Wheel Bearings?

The torque for wheel bearings varies depending on the specific vehicle make and model. It’s important to consult the manufacturer’s specifications or a professional mechanic for the correct torque value. Over-tightening or under-tightening can lead to premature wear or failure of the bearings.

How Tight Should You Tighten Wheel Bearings?

Tighten wheel bearings until snug, then back off slightly. Spin the wheel to check for smooth rotation without play. Adjust as needed. Always follow manufacturer’s specifications for precise torque settings. Over-tightening can lead to premature bearing wear. Regular maintenance ensures optimal performance and safety.

Do I Need A Torque Wrench For Wheel Bearings?

Yes, it is recommended to use a torque wrench when working on wheel bearings. Proper torque ensures that the bearings are tightened to the manufacturer’s specifications, preventing under or over tightening which can cause damage or premature wear. It’s important to use the correct torque specifications to ensure safety and longevity of the wheel bearings.

What Is The Torque Spec For Front Axle Nut?

The torque spec for front axle nut varies depending on the make and model of the vehicle. It is important to refer to the manufacturer’s specifications for the exact torque value. Generally, it ranges from 100 to 200 ft-lbs. It is recommended to use a torque wrench to ensure proper tightening.

Conclusion

Referencing manufacturer specifications is key. By following correct torque values, you maintain optimal functionality and prevent potential issues. Remember, precision in torque application is essential for the longevity of your vehicle’s wheel bearings.