To tighten wheel bearings, first, lift the vehicle and remove the wheel. Then, adjust the nut carefully.

Properly tightened wheel bearings ensure safe and efficient vehicle operation. Neglecting this maintenance task can lead to serious safety issues, such as wheel misalignment and overheating. By following the correct procedure, you can prevent costly repairs and ensure a smooth driving experience.

In this blog post, we will discuss the importance of wheel bearing maintenance and provide step-by-step instructions on how to tighten wheel bearings effectively. Let’s dive in and learn how to keep your vehicle running smoothly and safely.

Contents

What is Wheel Bearings?

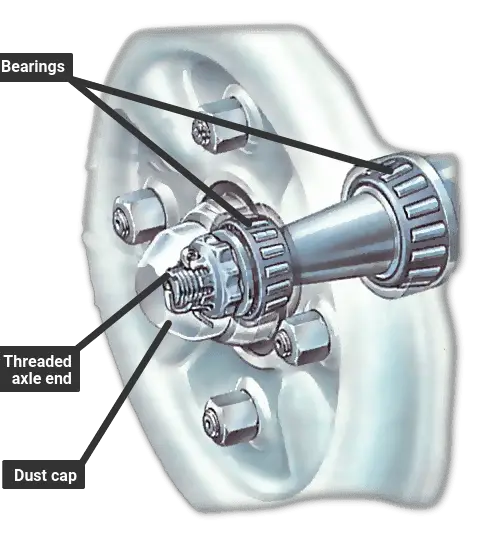

Wheel bearings are crucial components of a vehicle’s suspension system. They enable smooth rotation of the wheels and support the weight of the vehicle. Proper maintenance and regular inspection of wheel bearings are essential for ensuring safe and efficient operation of the vehicle.

The Role Of Wheel Bearings

Wheel bearings are responsible for reducing friction and supporting the vehicle’s weight. They allow the wheels to rotate smoothly while withstanding the forces exerted on them during vehicle operation. Properly functioning wheel bearings contribute to the vehicle’s stability and overall performance.

Signs Of Loose Wheel Bearings

It’s important to be vigilant for indications of loose wheel bearings, as they can significantly impact the vehicle’s safety and performance. Common signs of loose wheel bearings include abnormal tire wear, grinding or growling noises, and excessive play in the wheel.

Credit: www.howacarworks.com

Preparation And Safety Measures

Before you begin tightening the wheel bearings of your vehicle, it is important to take the necessary preparation and safety measures. By doing so, you can ensure a smooth and safe process while avoiding any potential accidents or injuries.

Tools And Materials Needed

Make sure you have the following tools and materials ready before starting the wheel bearing tightening process:

- Jack and jack stands

- Torque wrench

- Socket set

- Pliers

- Grease

- Clean cloth

Safety Precautions

When working with wheel bearings, it is crucial to follow these safety precautions:

- Always park your vehicle on a level and stable surface to prevent it from rolling or tipping over during the process.

- Engage the parking brake and chock the wheels to ensure the vehicle remains stationary.

- Wear safety goggles and gloves to protect your eyes and hands from any potential hazards.

- Refer to your vehicle’s manual to identify the specific torque specifications for your wheel bearings.

- Make sure to work in a well-ventilated area to prevent the inhalation of any harmful fumes.

- Before starting, inspect the wheel bearings for any signs of damage or wear. If they are worn out or damaged, they should be replaced instead of tightened.

- Ensure that you have a clear understanding of the tightening procedure before beginning. If you are unsure, consult a professional mechanic for guidance.

By taking these preparation steps and adhering to the necessary safety measures, you can proceed confidently with tightening the wheel bearings of your vehicle, ensuring optimal performance and safety.

How to Tighten Wheel Bearings

In this step-by-step guide, we will walk you through the process of tightening wheel bearings to help you keep your wheels in optimal condition.

Removing The Wheel And Hub

The first step in tightening wheel bearings is to remove the wheel and hub assembly. Here’s how you can do it:

- Loosen the lug nuts on the wheel using a lug wrench or a suitable tool.

- Lift the vehicle using a jack and secure it with jack stands for stability.

- Completely remove the lug nuts and take off the wheel.

- Locate the hub assembly, which is usually secured with a large nut or bolts.

- Remove the nut or bolts using the appropriate tools, and carefully detach the hub assembly from the wheel.

Adjusting The Wheel Bearings

Once the wheel and hub assembly are removed, it’s time to adjust the wheel bearings. Follow these steps:

- Clean the wheel bearings and inspect them for any signs of damage or wear. Replace them if necessary.

- Apply a thin layer of grease to the bearings to ensure smooth operation.

- Adjust the bearings by rotating the adjusting nut or using a bearing adjustment tool. Refer to your vehicle’s manual for the recommended torque specifications.

- Continue adjusting until you achieve the proper amount of play in the wheel. Too much play can cause instability, while insufficient play can lead to excessive friction and premature wear.

Reassembly And Testing

With the wheel bearings properly adjusted, it’s time to reassemble the wheel and hub assembly. Follow these final steps:

- Place the hub assembly back onto the wheel, ensuring it aligns correctly.

- Tighten the nut or bolts to secure the hub assembly in place, following the recommended torque specifications.

- Reinstall the wheel onto the hub and hand-tighten the lug nuts.

- Lower the vehicle back to the ground and remove the jack stands.

- Use a torque wrench to tighten the lug nuts to the manufacturer’s specifications.

- Finally, take your vehicle for a short test drive to ensure the wheel bearings are functioning properly and there are no unusual noises or vibrations.

Credit: forums.jag-lovers.com

Credit: www.youtube.com

Frequently Asked Questions

Here are some FAQs about tightening the wheel bearing –

Can You Tighten A Loose Wheel Bearing?

Yes, you can tighten a loose wheel bearing by adjusting it to the manufacturer’s recommended specifications.

How Tight Do I Tighten Wheel Bearings?

When tightening wheel bearings, you should follow the manufacturer’s instructions. Generally, the bearings should be tightened until there is no play in the wheel, but not so tight that it restricts movement. Always use a torque wrench to ensure proper tightness.

Over-tightening can lead to premature wear and damage.

How Do You Secure A Loose Bearing?

To secure a loose bearing, follow these steps:

1. Remove the bearing and clean the area.

2. Apply a bearing retainer or adhesive to the bearing and the surrounding area.

3. Reinstall the bearing and tighten it to the manufacturer’s recommended torque specification.

4. Allow the adhesive to dry and cure before using the equipment.

5. Regularly check the bearing for any signs of looseness and reapply the adhesive as needed.

How To Torque Wheel Bearings?

To torque wheel bearings, use a torque wrench and the manufacturer’s specifications. Tighten the nut to the recommended torque, usually around 50-60 ft-lbs. Follow the specific tightening sequence provided. Regularly check for any looseness or unusual noises.

Conclusion

Tightening wheel bearings is an important maintenance task that ensures the smooth operation and longevity of your vehicle’s wheels. By following the steps of how to tighten wheel bearings, you can ensure your wheels are secure and your ride is smooth. Stay safe on the road!