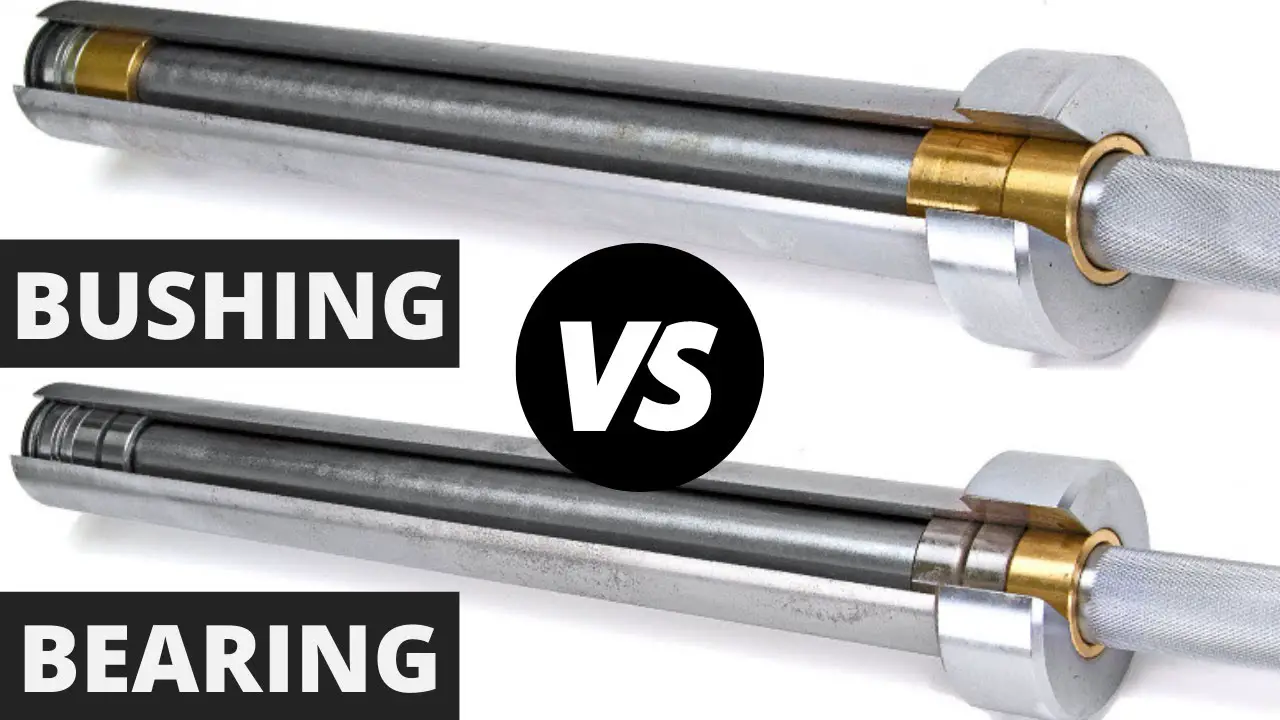

Bushing and bearing are components used in machinery for reducing friction and supporting rotating parts. Bushings are simple, cylindrical components that provide a bearing surface for a rotating shaft, while bearings are more complex, with rolling elements that reduce friction.

Both are essential for smooth and efficient operation of machinery. Bushings and bearings play a critical role in the functioning of various types of equipment, from vehicles to industrial machinery. Understanding Bushing Vs Bearing differences between these components is crucial for selecting the right option for specific applications.

We will explore the distinctions between bushings and bearings, their unique characteristics, and the factors to consider when choosing between them. By gaining insights into these essential components, you can make informed decisions that contribute to the optimal performance and longevity of your machinery.

Credit: m.youtube.com

Contents

Introduction To Bushing And Bearing

In the world of mechanical engineering, bushings and bearings play a crucial role in various applications. These components are responsible for reducing friction and allowing smooth rotation or movement between two parts.

While both bushings and bearings serve similar purposes, they have distinct characteristics and applications. In this article, we will explore the key functions and common applications of bushings and bearings, helping you understand their importance in different industries.

Key Functions

Bushings and bearings are designed to perform specific functions that enhance the efficiency and longevity of mechanical systems. Let’s take a closer look at their key functions:

- Support and Load Distribution: Both bushings and bearings provide support and distribute the load between two moving parts, reducing wear and tear. They minimize friction and ensure smooth movement, improving the overall performance of the system.

- Friction Reduction: The primary function of bushings and bearings is to reduce friction between two surfaces in contact. By incorporating materials with low coefficients of friction, they allow for efficient rotation or sliding motion, resulting in less energy loss and increased mechanical efficiency.

- Shock Absorption: Bushings and bearings also have the ability to absorb shocks and vibrations, protecting the components and preventing damage. This shock-absorbing property is particularly useful in applications where sudden impacts or oscillations occur.

- Alignment and Stability: Another crucial function of bushings and bearings is to ensure proper alignment and stability of rotating or sliding parts. They help maintain accurate positioning, preventing misalignment and reducing the risk of premature failure.

- Noise and Vibration Control: By minimizing friction and providing smooth motion, bushings and bearings contribute to noise reduction in mechanical systems. They help dampen vibrations, resulting in quieter operation and improved user experience.

Common Applications

Bushings and bearings find extensive use in various industries due to their versatile nature. Here are some common applications where these components are utilized:

| Bushing | Bearing |

|---|---|

|

|

These are just a few examples of where bushings and bearings are commonly employed. Their usage extends across numerous other applications, highlighting their significance in various sectors.

Bushings Materials And Design

Bushings are generally made of rubber, plastic, or metal. Rubber bushings are known for their ability to absorb vibrations and reduce noise. Plastic bushings are lightweight and resistant to corrosion, making them suitable for various applications. Metal bushings, such as bronze or steel, are preferred for heavy-duty use due to their durability and strength.

Advantages And Limitations

One of the key advantages of bushings is their ability to reduce friction and absorb shock, extending the lifespan of mechanical components. However, they may require regular maintenance and replacement due to wear and tear. Additionally, bushings are prone to deformation under heavy loads, which can impact their performance.

Bearings Types And Mechanisms

Bearings are critical components in various machines and mechanisms, facilitating smooth rotational or linear motion by reducing friction between moving parts.

Bearings come in diverse types, including ball bearings, roller bearings, plain bearings, and jewel bearings, each designed for specific applications.

Choosing The Right Bearing

Consider factors such as load capacity, speed, temperature, and environmental conditions when selecting the appropriate bearing for optimal performance.

Credit: bushingmfg.com

Credit: www.lily-bearing.com

Frequently Asked Questions

Here are some FAQs about the difference between bushing and bearing –

Why Use Bushing Instead Of Bearing?

Bushing is preferred over bearings due to its lower cost, simplicity, and ability to withstand higher loads. Bushings provide a sliding surface and reduce friction between two moving parts. They are also easier to install and require less maintenance compared to bearings.

What Is The Purpose Of A Bushing?

A bushing is a component used to reduce friction and wear between two moving parts. It is inserted into a hole in one part and serves as a bearing surface for a shaft or pin that passes through the other part.

The purpose of a bushing is to provide a smooth and durable surface for the rotating shaft.

What Is The Difference Between A Wheel Bearing And A Wheel Bushing?

A wheel bearing and a wheel bushing are both components that allow a wheel to rotate on its axle. However, a wheel bearing is a set of steel balls held together by a metal ring, while a bushing is made of rubber or polyurethane and fits into a metal sleeve.

Bearings are more durable and provide smoother rotation, while bushings are cheaper but less durable.

What Is The Difference Between A Bushing And A Thrust Bearing?

A bushing provides a bearing surface for rotary or linear motion, while a thrust bearing supports axial loads.

Conclusion

Understanding the bushings vs bearings is important for various applications. Both have unique characteristics and play important roles in machinery and equipment. By choosing the right component, you can optimize performance, efficiency, and longevity of your equipment. Make informed decisions based on your choice and needs.