If you’re a car enthusiast or considering purchasing a Ford 302 motor, one essential aspect to determine is whether it is a roller motor. A roller motor refers to an engine with roller lifters instead of flat-tappet lifters. Roller motors offer several advantages in terms of performance and longevity.

In this article, we’ll guide you through the process of identifying whether a 302 motor is equipped with roller lifters or not, along with the key differences between roller and non-roller motors.

Contents

What is a 302 Roller Motor?

A 302 roller motor refers to an engine equipped with roller lifters, which are cylindrical components that ride on the camshaft lobes. Unlike flat-tappet lifters commonly found in non-roller motors, roller lifters have a roller bearing that reduces friction and wear, resulting in smoother camshaft operation and increased durability.

Benefits of Roller Motors

Now that we understand what is roller motors, let’s explore the advantages of roller motors:

Reduced Friction and Wear

Roller lifters significantly reduce friction and wear between the camshaft lobes and the lifters, resulting in smoother operation and increased longevity of the engine.

Improved Performance and Efficiency

The reduced friction in roller motors allows the engine to run more efficiently, providing improved horsepower, torque, and overall performance.

Compatibility with Modern Camshaft Designs

Roller motors are compatible with modern camshaft designs that often have more aggressive profiles. This compatibility enables enthusiasts to take advantage of the latest advancements in camshaft technology.

Identifying a 302 Roller Motor

Determining whether a 302 motor is equipped with roller lifters requires a careful examination of various engine components. Here are the key steps to identify a roller motor:

Checking the Engine Block

The engine block can provide valuable information about the presence of roller lifters. Look for casting numbers or markings indicating roller-specific blocks, such as “F4TE” or “E7TE.” These markings suggest that the block was originally intended for a roller motor.

Examining the Camshaft

Inspecting the camshaft is another method to identify a roller motor. Roller camshafts typically have small, wheel-like lobes on which the roller lifters ride. Carefully remove the valve covers and visually examine the lobes. If you see smooth, rounded lobes with small wheels, it indicates the presence of a roller camshaft.

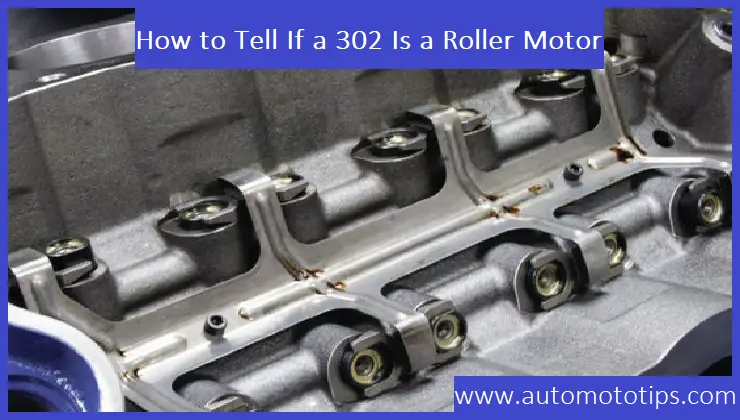

Looking for Roller Lifters

The most direct way to determine if a 302 motor has roller lifters is to visually inspect them. Remove the intake manifold and valve covers to gain access to the lifters. Roller lifters have a cylindrical body with a roller at the bottom, while non-roller lifters have a flat bottom surface. If you observe roller lifters, it confirms that the engine is a roller motor.

Inspecting the Timing Cover

Another clue lies in the timing cover. Roller motors often feature a specific timing cover design to accommodate the different lifter setups. Look for a slightly wider opening where the camshaft protrudes through the cover. This wider opening is necessary to accommodate the larger diameter of the roller lifters.

Verifying the Pushrods

Examining the pushrods can provide further evidence of a roller motor. Roller lifters require shorter pushrods than non-roller lifters. Measure the pushrods in your 302 motors and compare them to the specifications for a roller motor. If the pushrods are shorter, it suggests the presence of roller lifters.

Considering Other Factors

While the aforementioned methods are the primary means of identifying a roller motor, it’s important to note that engine components can be swapped or modified. In some cases, an engine may have a mix of roller and non-roller components. Therefore, it’s advisable to consider other factors, such as the engine’s history, documentation, or consulting with an experienced mechanic or engine builder.

Differences between a Roller and Non-Roller 302 Motor

Understanding the disparities between roller and non-roller 302 motors can help you make informed decisions about your engine choice. Here are some key differences to consider:

Performance and Power Delivery

Roller motors generally offer improved performance compared to non-roller motors. The reduced friction and more aggressive camshaft profiles of roller lifters allow for increased horsepower and torque. Roller motors often deliver smoother power delivery throughout the RPM range, making them ideal for high-performance applications.

Maintenance and Durability

One significant advantage of roller motors is their enhanced durability and reduced maintenance requirements. The roller lifters’ design reduces wear and friction, extending the lifter and camshaft lifespan. Additionally, roller lifters eliminate the need for regular valve lash adjustments associated with non-roller lifters, making maintenance less time-consuming.

Aftermarket Modifications

Roller motors provide greater flexibility for aftermarket modifications. The roller lifters’ ability to accommodate more aggressive camshaft profiles allows for increased customization and performance upgrades. Non-roller motors may require additional modifications to achieve similar performance gains.

How to Determine If a 302 Motor Is Not a Roller Motor

While identifying a roller motor, it’s equally important to be able to recognize a non-roller 302 motor. Here are some indicators that can help you determine if a 302 motor does not have roller lifters:

Understanding Flat-Tappet Camshafts

Non-roller motors typically use flat-tappet camshafts. These camshafts have flat lobes, lacking the distinctive wheel-like features seen on roller camshafts. Visual inspection of the camshaft can reveal the absence of roller lifters.

Identifying Non-Roller Lifters

Non-roller lifters have a flat bottom surface, unlike the cylindrical shape of roller lifters. By removing the intake manifold and valve covers, you can visually inspect the lifters. If you observe lifters with a flat surface, it indicates that the motor does not have roller lifters.

Examining Pushrod Guide Plates

Non-roller motors often utilize pushrod guide plates. These guide plates are typically mounted on the cylinder heads and serve to align the pushrods. If you notice the presence of guide plates, it suggests that the motor does not have roller lifters.

Checking for a Non-Roller Timing Chain

The type of timing chain used can also provide clues about whether the motor is a non-roller. Non-roller motors commonly feature a timing chain with a simpler design, without the necessary provisions for accommodating roller lifters. If you find a basic timing chain without any additional features, it indicates a non-roller motor.

It’s important to note that these methods are not exhaustive, and there may be exceptions or variations depending on the specific engine and modifications it has undergone. When in doubt, consulting an expert or referring to engine documentation can provide further clarification.

Frequently Asked Questions (FAQs)

Q: Can I convert a non-roller 302 engine to a roller motor?

A: Yes, it is possible to convert a non-roller 302 engine to a roller motor, but it requires specific components and expertise.

Q: Are roller motors more expensive than non-roller motors?

A: Generally, roller motors tend to be more expensive due to the additional components required for their construction.

Q: Are roller motors only found in specific car models?

A: Roller motors have been used in various Ford vehicles and can be found in both performance-oriented models and certain production vehicles.

Q: Can I use a non-roller camshaft in a roller motor?

A: It is not recommended to use a non-roller camshaft in a roller motor, as the design differences can lead to compatibility issues and potential damage.

Q: Can I install a roller camshaft in a non-roller 302 engine?

A: Installing a roller camshaft in a non-roller 302 engine requires extensive modifications, including changing the lifters, pushrods, and cylinder heads. It’s a complex process that should be performed by experienced engine builders or professionals.

Conclusion

Identifying whether a 302 motor is a roller motor or not is crucial for understanding its performance characteristics and maintenance requirements. Roller motors offer advantages in terms of power delivery, durability, and aftermarket customization. By examining engine components such as the camshaft, lifters, timing cover, and pushrods, you can determine if a 302 motor is equipped with roller lifters or not. Understanding the differences between roller and non-roller motors empowers you to make informed decisions regarding your engine choice and modifications.