As a professional writer, I understand that the topic of torque may not be the most exciting subject for everyone, but its importance cannot be overstated. Torque is a fundamental aspect of mechanics and is crucial in ensuring that machines and equipment work efficiently. It is the rotational force that is exerted on an object, and it is essential to understand how much torque is being transferred from one component to another.

One question that often arises in the world of mechanics is how much torque is lost through an extension. An extension is a tool used to lengthen the reach of a wrench or ratchet, and it is often used in hard-to-reach areas. However, the use of an extension can result in a loss of torque, which can affect the overall performance of the equipment. Therefore, it is crucial to understand the amount of torque that is lost through an extension to ensure that the machine or equipment is functioning at its best. In this article, we will explore this topic in-depth and provide you with everything you need to know about torque loss through an extension.

Contents

- 1 How Much Torque is Lost Through an Extension?

- 2 Frequently Asked Questions

- 2.1 What is an extension and how does it affect torque?

- 2.2 How much torque is typically lost through a 6-inch extension?

- 2.3 Can using multiple extensions increase torque loss?

- 2.4 Is it possible to compensate for torque loss through an extension?

- 2.5 What are some other factors that can affect torque accuracy?

- 2.6 Do Longer Extensions Result in more Torque Loss? Let’s find out

How Much Torque is Lost Through an Extension?

When working with power tools, the amount of torque that is delivered to the workpiece is critical to the success of the project. One factor that can impact the amount of torque that is delivered is the use of an extension. An extension can be a valuable tool, as it allows you to reach areas that are difficult to access. However, it can also result in a loss of torque, which can impact the quality of your work. In this article, we will explore how much torque is lost through an extension and what you can do to minimize this loss.

Factors That Impact Torque Loss

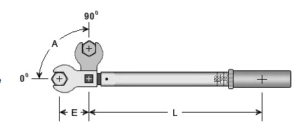

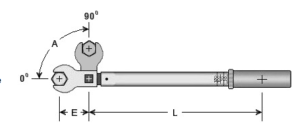

There are several factors that can impact the amount of torque that is lost when using an extension. The first factor is the length of the extension. The longer the extension, the more torque that will be lost. This is because the additional length creates more resistance, which reduces the amount of torque that is delivered to the workpiece. Another factor is the diameter of the extension. A larger diameter extension will result in less torque loss than a smaller diameter extension. This is because a larger diameter creates less resistance, which allows more torque to be delivered.

The type of extension that you use can also impact the amount of torque that is lost. A solid extension will result in less torque loss than a flexible extension. This is because a solid extension creates less resistance, which allows more torque to be delivered. Additionally, the material that the extension is made from can impact torque loss. A high-quality extension made from a durable material will result in less torque loss than a low-quality extension made from a weaker material.

Minimizing Torque Loss

While it is not possible to completely eliminate torque loss when using an extension, there are steps that you can take to minimize this loss. One of the most effective ways to minimize torque loss is to use the shortest extension possible. This will reduce the amount of resistance that the torque must overcome, which will allow more torque to be delivered to the workpiece. Additionally, using a larger diameter extension can also help to minimize torque loss.

Another way to minimize torque loss is to use a solid extension instead of a flexible extension. A solid extension will create less resistance, which will allow more torque to be delivered. Additionally, using a high-quality extension made from a durable material can also help to minimize torque loss. This is because a high-quality extension will be less likely to flex or bend, which will create less resistance and allow more torque to be delivered.

Final Thoughts

When using an extension with a power tool, it is important to be aware of the potential loss of torque that can occur. By understanding the factors that impact torque loss and taking steps to minimize this loss, you can ensure that you are delivering the maximum amount of torque possible to the workpiece. This will result in a higher quality finished product and greater satisfaction with your work.

Frequently Asked Questions

Here are some common questions about how much torque is lost through an extension:

What is an extension and how does it affect torque?

An extension is a tool that allows you to reach bolts and nuts in tight or hard-to-reach places. The longer the extension, the more torque is lost. This is because the extension acts as a lever, and the farther away the force is applied from the bolt or nut, the less effective that force becomes. Additionally, the friction between the extension and the socket can also cause some torque loss.

Extensions are often used in automotive and industrial settings where bolts and nuts are commonly located in hard-to-reach areas. It’s important to be aware of the torque loss that extensions can cause, as this can affect the accuracy of torque measurements and potentially lead to equipment failure.

How much torque is typically lost through a 6-inch extension?

The amount of torque lost through an extension depends on a number of factors, including the length of the extension and the amount of friction between the extension and the socket. However, as a rule of thumb, a 6-inch extension can cause a torque loss of around 10-15%.

It’s important to note that this is just an estimate and actual torque loss can vary. To ensure accurate torque measurements, it’s recommended to use the shortest extension possible for the job at hand and to factor in the expected torque loss when setting torque values.

Can using multiple extensions increase torque loss?

Yes, using multiple extensions can increase torque loss. Each extension adds to the overall length of the tool, which can compound the amount of torque lost. Additionally, the more extensions used, the more potential there is for misalignment between the tool and the bolt or nut, which can further reduce torque effectiveness.

If multiple extensions are necessary for a job, it’s important to use them in the correct order and to be aware of the additional torque loss that each extension can cause. It’s also recommended to use extensions with a high-quality finish to reduce friction and maintain accuracy.

Is it possible to compensate for torque loss through an extension?

Yes, it’s possible to compensate for torque loss through an extension by adjusting the torque value to account for the expected loss. This can be done by using a torque wrench with a built-in torque loss calculator or by manually adjusting the torque value based on the length of the extension being used.

It’s important to note that compensating for torque loss is not a perfect solution and can lead to inaccuracies in torque measurements. For this reason, it’s recommended to use the shortest extension possible for the job at hand and to be aware of the expected torque loss when setting torque values.

What are some other factors that can affect torque accuracy?

In addition to extensions, there are several other factors that can affect torque accuracy, including the quality of the tool being used, the condition of the bolt or nut being tightened, and the technique used to apply torque. It’s important to use high-quality tools and to follow proper torque procedures to ensure accurate measurements and prevent equipment failure.

Additionally, it’s important to use a torque wrench that is calibrated regularly to ensure accuracy. Over time, torque wrenches can become less accurate due to wear and tear, so it’s important to have them calibrated by a professional on a regular basis.

Do Longer Extensions Result in more Torque Loss? Let’s find out

In conclusion, understanding the amount of torque lost through an extension can be critical in various mechanical applications. It is crucial to note that the amount of torque lost depends on several factors, including the length of the extension, the diameter of the extension, and the material used. It is also important to note that torque loss can have a significant impact on the performance and efficiency of a mechanical system.

As a professional writer, I highly recommend that engineers and technicians keep in mind the torque loss when using extensions. By doing so, they can ensure that their mechanical systems are running as efficiently as possible. Additionally, it is important to always use high-quality extensions made from durable materials to reduce the amount of torque lost. By taking these steps, we can improve the performance of our mechanical systems and ensure that they continue to operate at their best for years to come.