NGK Spark Plugs are made in various countries worldwide, including Japan, the United States, India, Thailand, China, and South Africa. These global manufacturing facilities ensure that NGK Spark Plugs meet high-quality standards and fulfill the growing demand across automotive markets.

NGK Spark Plugs, a leading name in the spark plug industry, has a long history of innovation and quality in producing automotive ignition components. The company, founded in 1936 in Nagoya, Japan, has since expanded its reach globally to meet the ever-growing demand for its products. Over the years, NGK Spark Plugs has established manufacturing facilities in multiple countries to serve the diverse markets across the world. These facilities not only produce spark plugs but also oxygen sensors, glow plugs, and other automotive components, ensuring that NGK remains a top choice for automotive enthusiasts and professionals alike.

This article will delve into the various locations where NGK Spark Plugs are made, the company’s global impact, and how it ensures the highest standards of quality across all its manufacturing plants.

Contents

- 1 Where Are NGK Spark Plugs Made?

- 2 Quality Control Across Manufacturing Facilities

- 3 Frequently Asked Questions

- 4 Conclusion

Where Are NGK Spark Plugs Made?

NGK Spark Plugs operates in several countries across the globe. With state-of-the-art facilities and highly skilled workers, the company has successfully established a strong foothold in key automotive markets. Below, we explore the different manufacturing locations of NGK Spark Plugs.

1. Japan: The Heart of NGK Spark Plugs

As the birthplace of NGK Spark Plugs, Japan remains the central hub of its operations. The company’s global headquarters is located in Nagoya, Aichi Prefecture, Japan, where NGK was founded. Over the years, Japan has continued to serve as the heart of NGK Spark Plugs’ research and development (R&D) activities. The country is also home to the largest manufacturing facility, located on Kyushu Island.

Manufacturing Facilities in Japan

- Miyanojo Factory, Kyushu Island: This facility is responsible for producing millions of automotive spark plugs, oxygen sensors, and other ignition-related components each year. The Miyanojo factory represents NGK’s commitment to innovation and cutting-edge technology. This plant uses advanced robotics and automated systems to ensure that the manufacturing process remains efficient and precise, maintaining the high quality NGK is known for globally.

- Technical Research Center, Nagoya: Located at the headquarters in Nagoya, this center focuses on the development of new ignition technologies and ensuring that all products meet the stringent performance requirements. The research center works hand-in-hand with the production facilities to enhance the overall quality of the products made in Japan.

The Miyanojo factory, combined with the research center in Nagoya, ensures that Japan remains at the forefront of NGK Spark Plugs’ global operations.

2. United States: Expanding Reach and Meeting Demand

In the United States, NGK Spark Plugs operates several manufacturing and R&D facilities, producing spark plugs, oxygen sensors, and glow plugs to meet the diverse demands of the American automotive market. NGK’s presence in the U.S. dates back to the late 1970s, and it has since grown into one of the leading manufacturers of spark plugs in North America.

Key NGK Manufacturing Locations in the U.S.

- Irvine, California: This facility, located in Southern California, began production in 1978. It produces a wide range of spark plugs and ignition components for the U.S. market. In addition to manufacturing, the Irvine plant plays a vital role in customer support, helping meet the technical needs of customers across the country.

- Sissonville, West Virginia: Established in 1994, this plant focuses on the production of oxygen sensors and spark plugs. With its proximity to major automotive hubs, Sissonville plays a crucial role in serving both the North American and global automotive markets. The plant’s capabilities include a strong focus on environmental standards and the development of advanced sensor technology.

- Wixom, Michigan: This facility is home to NGK’s North American Technical Center, where the company focuses on R&D for spark plugs and other automotive components. The Wixom site works to support both NGK’s U.S. manufacturing facilities and customers by continuously improving product designs and performance.

The U.S. market is essential for NGK Spark Plugs, and these facilities ensure that NGK meets the growing demand for automotive components across the region.

3. India: Catering to the Growing Automotive Industry

In India, NGK Spark Plugs operates a production facility that caters to the growing demand for automotive parts in the Indian and South Asian markets. India has emerged as one of the world’s fastest-growing automotive markets, and NGK has capitalized on this by establishing a manufacturing base in the region.

NGK Manufacturing Facility in India

- Bawal, Haryana: NGK Spark Plugs (India) Pvt. Ltd. operates this facility, producing spark plugs, glow plugs, and oxygen sensors. The Bawal facility ensures that NGK can meet the high demand for ignition components in India’s rapidly expanding automotive sector. This plant not only supplies products to the Indian market but also exports to various countries in the region.

By maintaining a local manufacturing presence, NGK Spark Plugs can effectively serve the Indian market, which continues to experience growth in both the domestic and export markets.

4. Thailand: Strategic Location for Southeast Asia

NGK Spark Plugs also has a manufacturing plant in Thailand, which plays an essential role in supplying spark plugs and ignition components to Southeast Asia. This location provides NGK with a strategic advantage, allowing it to meet the needs of the growing automotive market in the region.

NGK Manufacturing Facility in Thailand

- Chonburi, Thailand: This plant is responsible for producing a variety of spark plugs and other automotive components for the Southeast Asian market. It also focuses on manufacturing oxygen sensors, contributing to the growing demand for environmentally-friendly automotive technologies. The plant in Thailand allows NGK to meet the needs of both domestic and international customers in the region.

5. China: Meeting the Demand in Asia

China is another critical market for NGK Spark Plugs. The company operates a manufacturing facility in Shanghai, where it produces spark plugs, oxygen sensors, and other ignition-related components for the Chinese automotive market and beyond.

NGK Manufacturing Facility in China

- Shanghai, China: The Shanghai plant was NGK’s first production base in China and plays a vital role in supplying products for both domestic and international customers. The plant produces a wide variety of spark plugs, ensuring that NGK can meet the growing demand for automotive parts in one of the largest automotive markets in the world.

While some consumers have raised concerns over the quality of products made in China, NGK maintains its rigorous quality control processes to ensure that products made at the Shanghai facility meet the same standards as those produced in Japan and other locations.

6. South Africa: Serving the EMEA Region

NGK Spark Plugs also operates a manufacturing facility in South Africa, which serves the EMEA (Europe, Middle East, and Africa) region. The South African plant produces millions of spark plugs each year, ensuring that NGK can meet the demand for ignition components across a large and diverse region.

NGK Manufacturing Facility in South Africa

- Gauteng, South Africa: The South African plant produces a wide range of automotive components, including spark plugs and oxygen sensors. With its focus on high-volume production, the facility is crucial in meeting the needs of the EMEA market and supporting NGK’s operations in Africa and the Middle East.

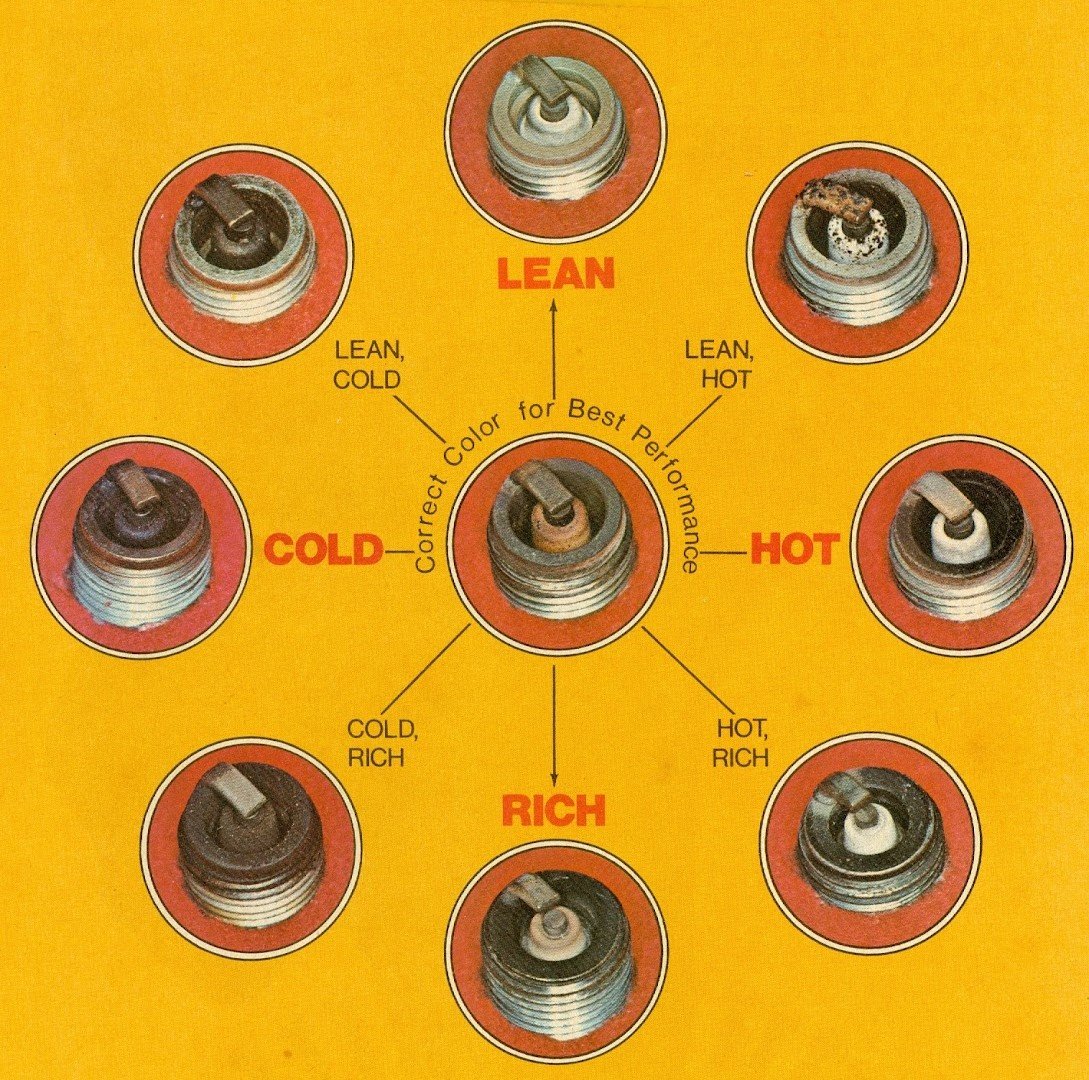

Quality Control Across Manufacturing Facilities

NGK Spark Plugs is known for its commitment to quality, and the company’s global network of manufacturing facilities is no exception. Whether in Japan, the United States, India, Thailand, China, or South Africa, NGK maintains strict quality control standards to ensure that each spark plug meets the company’s high-performance benchmarks.

Each plant uses advanced technology, automated systems, and manual checks to ensure that spark plugs are produced with precision. Additionally, NGK has a robust research and development program to continuously improve the performance of its products. Through collaboration between its global manufacturing plants and R&D centers, NGK ensures that its spark plugs deliver optimal performance, durability, and reliability.

Frequently Asked Questions

Here are some FAQs about manufacturing locations of NGK Spark Plugs –

1. Are NGK Spark Plugs made in Japan better than those made in other countries?

While NGK Spark Plugs are known for their high-quality manufacturing processes, products made in Japan may have some slight differences compared to those made in other countries. However, NGK ensures that all of its manufacturing plants, regardless of location, adhere to the same strict quality control standards.

2. Where is the NGK Spark Plugs headquarters located?

The global headquarters of NGK Spark Plugs is located in Nagoya, Japan, where the company was founded.

3. Does NGK Spark Plugs have a presence in India?

Yes, NGK Spark Plugs (India) Pvt. Ltd. operates a manufacturing facility in Bawal, Haryana, producing spark plugs, glow plugs, and oxygen sensors.

4. How many spark plugs does NGK produce annually?

NGK Spark Plugs produces millions of spark plugs annually across its global manufacturing facilities, with significant production volumes in countries like Japan, the United States, and South Africa.

5. Are NGK Spark Plugs used in motorsports?

Yes, NGK Spark Plugs has been involved in motorsports, including partnerships with teams in Formula 1, MotoGP, and the Dakar Rally.

Conclusion

NGK Spark Plugs are produced in multiple countries worldwide, including Japan, the United States, India, Thailand, China, and South Africa. Each of these manufacturing facilities plays a critical role in meeting the global demand for high-quality automotive ignition components. From the company’s headquarters in Japan to its facilities across the globe, NGK maintains rigorous quality standards to ensure that its products perform reliably and efficiently in a variety of vehicles and applications.

As the automotive industry continues to grow and evolve, NGK Spark Plugs remains at the forefront of innovation, providing spark plugs that meet the demands of modern engines. Whether you are looking for spark plugs for your car, motorcycle, or other machinery, NGK continues to be a trusted choice for drivers and mechanics around the world.