What Are Spark Plugs Made Of? Spark plugs are made from steel, ceramic, and metals like copper, platinum, or iridium. These materials ensure durability, heat resistance, and conductivity for optimal engine performance.

Spark plugs are important components in internal combustion engines, responsible for igniting the air-fuel mixture within the engine. Despite their small size, they play a pivotal role in ensuring smooth engine operation. Spark plugs are made from a combination of materials, each chosen for its specific properties to withstand the harsh conditions inside the engine. These materials include steel for the outer shell, ceramic for the insulator, and metals like copper, platinum, or iridium for the electrodes.

In this article, we’ll explore these materials in detail, their functions, and how they contribute to the performance and longevity of your vehicle’s engine.

Contents

What Are Spark Plugs Made Of?

The composition of a spark plug includes various components, each made from specific materials to handle different functions within the engine. These materials need to perform at the highest level under extremely tough conditions. Below, we’ll break down each component of a spark plug and explain the materials used in detail.

1. Outer Shell – Made of Steel or Nickel Alloys

The outer shell of a spark plug plays an important role in protecting the internal parts from damage caused by high temperatures and pressures within the engine. This component must be strong enough to keep the spark plug securely in place and withstand the wear and tear of continuous engine operation.

- Steel: The majority of spark plugs have an outer shell made of steel, which offers high strength and durability. Steel can withstand high temperatures and is resistant to corrosion, making it a reliable material for the outer casing of spark plugs.

- Nickel Alloys: For high-performance or specialized spark plugs, nickel alloys are sometimes used. Nickel alloys offer excellent resistance to heat and oxidation, which is crucial in performance engines that experience more intense heat cycles. They are often used in spark plugs intended for racing cars or other high-performance vehicles.

The outer shell’s durability is essential because it must maintain its integrity even after repeated cycles of extreme temperature changes within the combustion chamber.

2. Insulator – Made of Ceramic Material

The insulator is another essential component of a spark plug. It is made of a high-quality ceramic material that provides electrical insulation, preventing the electrical charge from leaking out of the center electrode. Additionally, the insulator helps dissipate the heat generated by the spark plug, ensuring that it remains operational in the engine’s harsh environment.

- Ceramic: Ceramic materials are chosen for their exceptional heat resistance and insulating properties. The high temperature that spark plugs reach during operation (often exceeding 2,000°F or 1,093°C) requires materials that can both insulate and absorb heat without degrading. Ceramic is perfect for this purpose, and its ability to handle extreme temperatures makes it one of the most common materials used in spark plug insulators.

Ceramic is also lightweight, which is beneficial in reducing the overall weight of the spark plug, an important factor in performance vehicles.

3. Center Electrode – Made of Copper, Platinum, or Iridium

The center electrode is the component through which the electrical current flows from the ignition system, creating the spark that ignites the fuel-air mixture inside the engine. The material used for the center electrode must be both conductive and resistant to heat, as it undergoes intense heat cycles every time the engine runs.

- Copper: Copper is one of the most common materials used in spark plug center electrodes due to its excellent electrical conductivity. Copper spark plugs are often used in older vehicles or those with less demanding engine requirements. While copper provides excellent spark efficiency, it tends to wear down faster than other materials, requiring more frequent replacements.

- Platinum: Platinum is more durable than copper, which makes it ideal for modern vehicles. It has higher resistance to wear and corrosion, making platinum spark plugs last much longer—often up to 60,000 miles or more. Platinum electrodes allow for a more consistent spark over time, improving fuel efficiency and reducing engine misfires.

- Iridium: Iridium is one of the most advanced materials used in spark plugs. It is even more durable and heat-resistant than platinum, making it the top choice for performance vehicles. Iridium spark plugs can last up to 100,000 miles or more and provide superior ignition performance, which is why they are commonly found in high-end vehicles. Iridium’s hardness and high melting point make it an ideal material for electrodes that need to withstand extreme conditions without degrading.

4. Ground Electrode – Made of Nickel or Platinum

The ground electrode works with the center electrode to create the spark that ignites the air-fuel mixture. The material of the ground electrode must be durable enough to resist the wear caused by electrical arcing, heat, and the pressure inside the engine.

- Nickel: Nickel is the most common material used for ground electrodes in standard spark plugs. It is cost-effective, durable, and resistant to corrosion. However, nickel tends to wear out faster than platinum or iridium when subjected to extreme engine conditions.

- Platinum: Some spark plugs use platinum for the ground electrode to improve durability. Platinum ground electrodes reduce wear and improve spark efficiency, which is why they are often found in long-lasting spark plugs that are designed to go for tens of thousands of miles.

5. Sealing Gasket – Made of Steel or Aluminum

The sealing gasket is a critical part of the spark plug, ensuring that the spark plug fits tightly into the engine without any gaps. It prevents the leakage of gases from the combustion chamber and ensures that the spark plug maintains proper compression. The materials used for the gasket must be able to handle the pressure and heat within the engine.

- Steel: Steel is often used for the sealing gasket because of its strength and resistance to wear. Steel can withstand the high temperatures and pressure inside the engine, providing a tight seal and preventing leaks.

- Aluminum: In some spark plugs, aluminum is used for the gasket because it is lighter and offers excellent corrosion resistance. Aluminum gaskets are more commonly found in specialized or performance spark plugs.

Why Are Different Materials Used in Spark Plugs?

Each material used in spark plugs is selected for its unique properties. For instance, copper is used for its excellent conductivity, while iridium and platinum are chosen for their superior durability and heat resistance. The choice of material influences not only the spark plug’s performance but also its longevity, engine efficiency, and fuel economy.

Here’s why different materials are necessary for various components:

- Conductivity: The center electrode must be made of a highly conductive material, such as copper, platinum, or iridium, to ensure the spark is strong enough to ignite the fuel-air mixture.

- Heat Resistance: Spark plugs must withstand extreme temperatures in the combustion chamber, often exceeding 2,000°F. Materials like ceramic, platinum, and iridium excel at handling these high temperatures without degrading.

- Durability: Materials such as platinum and iridium are more resistant to wear and corrosion, which makes them ideal for long-lasting spark plugs that require less frequent replacement.

How Spark Plug Materials Impact Engine Performance

The materials used in spark plugs can have a significant impact on how your engine runs. Here’s a breakdown of how different materials affect engine performance:

1. Improved Fuel Efficiency

Spark plugs made of platinum or iridium ensure a more consistent spark, which leads to better fuel combustion. As a result, these spark plugs can improve fuel efficiency and save you money on gas in the long run.

2. Longer Lifespan

Spark plugs made from iridium or platinum last much longer than those made from copper. This means fewer replacements and less maintenance, which is especially beneficial for those who own high-mileage vehicles. Read more about the How Long Do Spark Plugs Last?

3. Better Engine Performance

The right spark plug materials can result in smoother engine operation, fewer misfires, and quicker acceleration. This is why high-performance vehicles often use spark plugs made from iridium, which provide better conductivity and durability.

Frequently Asked Questions

Here are some FAQs about spark plug materials –

1. What are the most common materials used in spark plugs?

The most common materials are steel (for the outer shell), ceramic (for the insulator), and copper (for the center electrode). Platinum and iridium are often used in high-performance spark plugs.

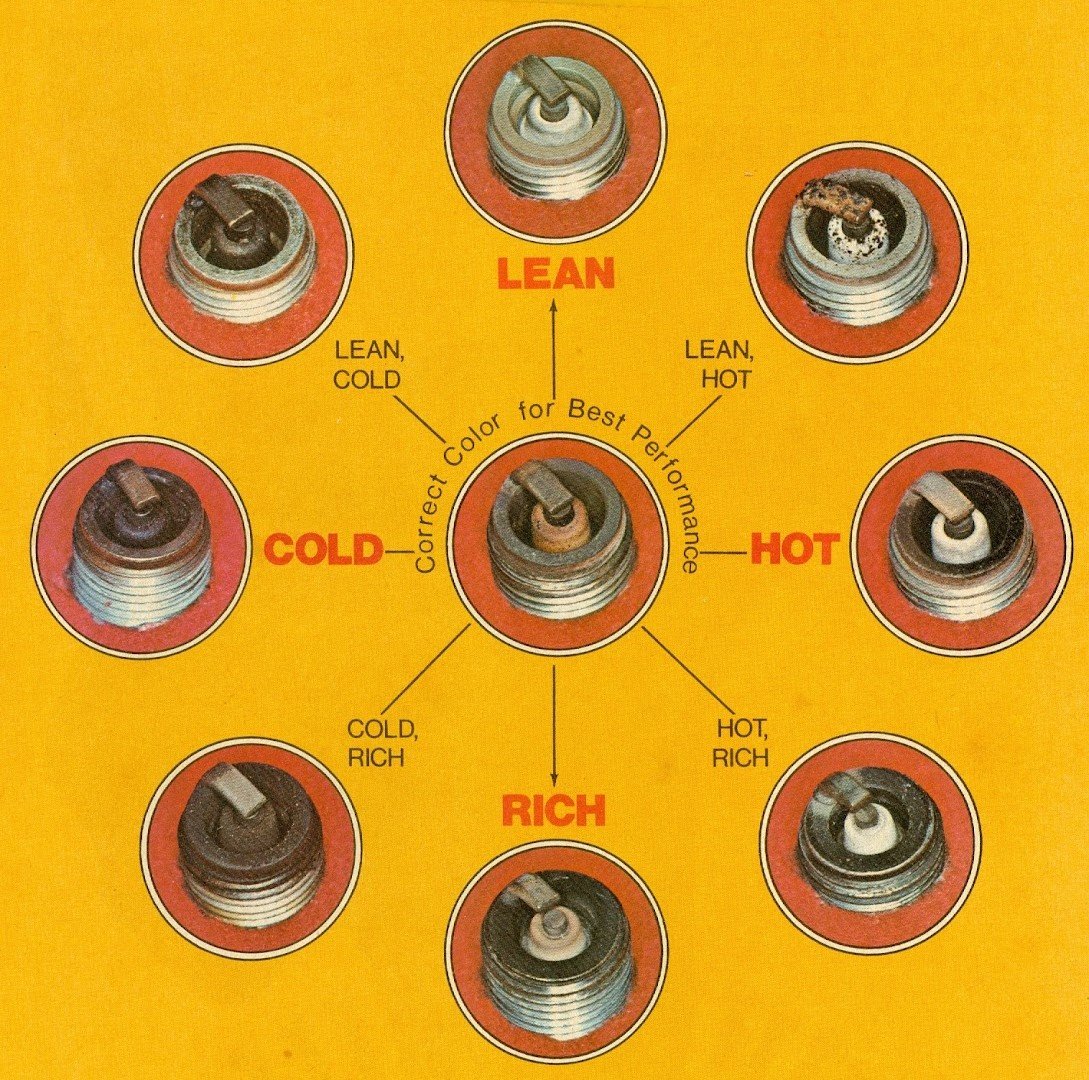

2. Why do spark plugs wear out?

Spark plugs wear out due to the intense heat and pressure inside the engine. The electrodes can degrade over time, leading to poor engine performance and the need for replacement.

3. How often should spark plugs be replaced?

Spark plugs typically need to be replaced every 20,000 to 100,000 miles, depending on the material. Copper spark plugs need more frequent replacement, while iridium and platinum spark plugs last longer.

4. Can I use iridium spark plugs in any vehicle?

Iridium spark plugs are compatible with most modern vehicles, particularly those that require high-performance plugs. However, it’s always best to check your vehicle’s specifications before upgrading.

5. What happens if the wrong spark plug material is used?

Using the wrong spark plug material can result in poor performance, engine misfires, and reduced fuel efficiency. It’s essential to choose the right spark plug based on your vehicle’s needs.

Conclusion

Spark plugs are made from a variety of materials, including steel, nickel alloys, ceramic, copper, platinum, and iridium. Each material plays a vital role in ensuring that the spark plug performs effectively under the harsh conditions of the engine. The right choice of materials ensures longevity, efficiency, and optimal engine performance. Knowing the spark plugs materials can help you make an informed decision about which spark plugs are best for the vehicle, whether you’re looking for durability, cost-effectiveness, or high performance.