How to fix a stripped spark plug hole involves cleaning the damaged threads, enlarging the hole if necessary, and using a spark plug hole repair kit to insert a new thread insert. Once the new insert is securely in place, reinstall the spark plug with the proper torque to restore engine function and prevent future issues.

A stripped spark plug hole can be a troublesome issue, especially if you’re working with an older vehicle or a cylinder head that has been over-tightened during previous spark plug replacements. Stripping the threads inside the spark plug hole can prevent the spark plug from being properly secured, leading to engine misfires, loss of power, and potential damage to other components. While fixing a stripped spark plug hole might sound intimidating, it’s a repair you can tackle with some patience and the right tools.

In this guide, we’ll walk you through the process of repairing a stripped spark plug hole in detail, helping you restore the functionality of your engine.

Contents

What is a Stripped Spark Plug Hole?

A stripped spark plug hole occurs when the threads inside the cylinder head that hold the spark plug become damaged. This can happen for several reasons, including over-tightening the spark plug, cross-threading it, or using an improper spark plug size. When the threads are damaged, the spark plug can’t be properly secured, which may cause it to become loose and lead to engine misfires, poor performance, and even engine damage.

In some cases, you may also experience oil leakage or coolant leakage around the spark plug. If left untreated, a stripped spark plug hole can cause significant damage to the engine, so it’s essential to repair it promptly.

How to Fix a Stripped Spark Plug Hole

To repair a stripped spark plug hole, you’ll need the right set of tools. While some may already be in your toolbox, you may need to purchase or rent a few items specifically designed for this repair. Here’s a complete list of tools and materials you will need:

- Spark Plug Hole Repair Kit: This kit usually includes all the components required to repair the stripped hole, such as inserts or helicoils.

- Drill and Drill Bits: If the hole needs to be enlarged for the insert, you’ll need a drill and the correct size drill bits.

- Tap and Die Set: For re-threading the hole, a tap from the kit will help you create new threads inside the hole.

- Thread Chaser or Cleaner: This tool helps clean any remaining debris from the damaged threads.

- Torque Wrench: To ensure you tighten the spark plug to the correct torque specification.

- Anti-Seize Lubricant: This helps to prevent future seizing of the spark plug and makes removal easier during future maintenance.

- Safety Gear: Wear gloves, safety glasses, and a face mask for protection.

Optional Tools

- Vacuum Cleaner or Compressed Air: To clean out any debris before beginning the repair process.

- Socket Set: For removing the spark plug and any other bolts or components obstructing the area.

Step-by-Step Process for Fixing a Stripped Spark Plug Hole

Now that you have your tools and materials ready, let’s walk through the detailed steps for fixing a stripped spark plug hole. This process involves several key stages: preparation, removal of the damaged spark plug, cleaning, repairing the threads, and reinstalling the spark plug.

1. Preparation: Safety First

Before you begin any work, make sure that the engine is off and completely cool. Working with a hot engine can lead to burns and discomfort. Always disconnect the vehicle’s battery to prevent any electrical accidents during the repair. Make sure you are in a well-lit area, and use a clean cloth to wipe away any dirt or debris around the spark plug hole.

Important Safety Tips:

- Wear safety gloves and glasses to protect yourself from any sharp objects or debris that might fall into the engine.

- Make sure there are no flammable materials nearby when working with tools around the engine.

2. Remove the Damaged Spark Plug

Before you begin repairing the stripped spark plug hole, you’ll need to remove the damaged spark plug. This step is essential to assess the extent of the damage and prepare the hole for the repair process.

- Step 1: Loosen the Spark Plug: Using a spark plug socket and a ratchet wrench, carefully loosen the spark plug in the stripped hole. If the spark plug is stuck, spray some penetrating oil and let it sit for a few minutes. Afterward, gently work the spark plug out of the hole, taking care not to damage the surrounding threads any further.

- Step 2: Inspect the Hole: Once the spark plug is removed, examine the hole for damage. You should be able to see whether the threads are completely stripped or just partially damaged. If the threads are completely gone, you’ll need to proceed with the next steps to restore them.

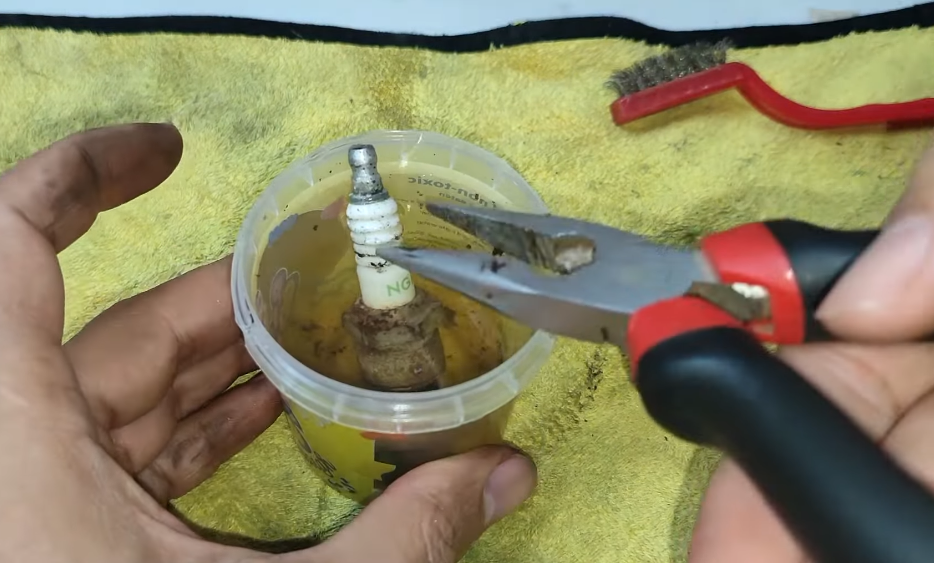

3. Cleaning the Hole

Before repairing the hole, you must clean the existing threads. This is an essential step because dirt, debris, or oil inside the hole can interfere with the repair process. Use a thread chaser or a cleaning brush to remove any debris and residue around the spark plug hole. If you have access to compressed air or a vacuum, use them to blow out any debris from inside the hole.

4. Repairing the Threads

This is the critical part of the repair process, and it involves re-threading the hole to make it suitable for a new spark plug. Here’s how you can do it:

- Step 1: Drill the Hole: In some cases, the existing hole may need to be enlarged slightly to fit the repair insert. Using a drill and a drill bit that matches the size specified in your repair kit, carefully enlarge the hole to prepare it for the insert. Be gentle and make sure to drill straight to avoid any misalignment.

- Step 2: Tap the Hole: Once the hole is drilled to the correct size, you’ll need to tap new threads. Using a tap tool from the repair kit, insert the tap into the hole and turn it slowly to cut new threads. Be sure to apply some cutting oil to reduce friction and make the process smoother. Tap the hole until you reach the bottom, but be careful not to over-tap, as this can damage the cylinder head.

- Step 3: Insert the Repair Insert: With the new threads in place, it’s time to insert the repair insert. Depending on the repair kit you’re using, this may involve inserting a helicoil or a solid threaded insert into the hole. Use a tool to drive the insert into place, ensuring it is seated securely. This insert provides a new, stable set of threads for the spark plug to grip onto.

5. Reinstalling the Spark Plug

Now that the spark plug hole is repaired, it’s time to reinstall the spark plug. Before installing the spark plug, apply a small amount of anti-seize lubricant to the spark plug threads. This will prevent the spark plug from seizing in the future, making it easier to remove during the next maintenance cycle.

- Step 1: Insert the Spark Plug: Carefully thread the spark plug into the new insert. Make sure you do this by hand at first to ensure it goes in straight and doesn’t cross-thread.

- Step 2: Tighten the Spark Plug: Once the spark plug is threaded in properly, use a torque wrench to tighten it to the manufacturer’s recommended torque specification. Over-tightening or under-tightening the spark plug can cause problems down the line, so this step is crucial.

6. Test the Repair

Once the spark plug is installed, reconnect the battery and start the engine. Let the engine run for a few minutes and listen for any unusual noises, such as misfires or sputtering. If the engine runs smoothly and there are no issues with the spark plug hole, your repair is successful.

Tips for Success

While repairing a stripped spark plug hole can be straightforward, there are a few key tips to ensure your repair is successful and long-lasting. By following these best practices, you can avoid common mistakes and achieve the best possible results.

- Take Your Time: This repair requires precision. Rushing through any step could lead to further damage, so take your time to ensure each part of the repair is done correctly.

- Cleanliness is Key: Keep the area around the spark plug hole clean throughout the process to prevent any debris from entering the engine.

- Use the Correct Tools: Using the correct size tap, drill, and insert is essential for a successful repair. Always check your repair kit for the right specifications.

When to Seek Professional Help

While repairing a stripped spark plug hole is a manageable DIY task for most car owners, there are cases where professional assistance is recommended. If you notice that the threads are severely damaged, or if you’re uncomfortable using the necessary tools, it might be best to consult a professional mechanic. Professionals have the experience and equipment to handle complex repairs, ensuring that your engine is restored to its optimal performance.

Frequently Asked Questions

Here are some FAQs about fixing a stripped spark plug hole –

1. What causes a spark plug hole to strip?

Over-tightening, using the wrong spark plug size, or cross-threading can cause the threads inside the spark plug hole to strip.

2. Can I drive with a stripped spark plug hole?

It is not recommended to drive with a stripped spark plug hole, as it can lead to engine misfires and potential engine damage.

3. How much does it cost to fix a stripped spark plug hole?

Fixing a stripped spark plug hole can cost between $50 to $200 depending on whether you use a DIY kit or hire a professional mechanic.

4. Can I fix a stripped spark plug hole myself?

Yes, you can fix a stripped spark plug hole yourself with the proper tools and a bit of patience. It’s a straightforward repair for those with basic mechanical skills.

5. How can I prevent a spark plug hole from stripping?

To prevent a stripped spark plug hole, ensure that you use the correct spark plug size, avoid over-tightening, and be careful not to cross-thread when installing the spark plug.

Conclusion

A stripped spark plug hole doesn’t have to be a costly or stressful issue. With the right tools and some patience, you can fix the problem yourself and save money on costly professional repairs. By following the steps outlined in this guide, you’ll be able to repair the spark plug hole, restore engine performance, and get your vehicle back on the road in no time.

Remember, the key to success lies in being thorough and taking your time during each step of the process. If you follow these instructions carefully, you can fix a stripped spark plug hole without needing to replace the entire cylinder head or face expensive repairs.