How to check spark plug wires: Inspect for visible damage, test resistance with a multimeter, and check for spark leakage. Replace any faulty wires to maintain engine performance.

Spark plug wires, also known as ignition wires, are an essential part of your car’s ignition system. These wires carry high voltage from the ignition coil to the spark plugs, enabling the engine to fire and run smoothly. Over time, spark plug wires can deteriorate, causing poor engine performance, misfires, and even starting issues.

Knowing how to check spark plug wires is an important skill for every car owner. This guide will guide you how to inspect, test, and maintain your spark plug wires, ensuring that your engine continues to perform at its best.

Contents

How to Check Spark Plug Wires

Before diving into the steps, it’s important to gather the proper tools for testing your spark plug wires. Here’s what you’ll need:

- Digital Multimeter (DMM): For measuring the resistance of the spark plug wires.

- Spark Plug Wire Puller: To safely remove the wires from the spark plugs and ignition coil without damaging them.

- Flashlight: Useful for inspecting the wires in low-light conditions.

- Spray Bottle with Water: For testing spark leakage by spraying water along the wires while the engine is running.

- Safety Gear: Gloves and safety glasses are recommended to protect yourself while working under the hood.

Having these tools ready will make the process smooth and help you conduct accurate tests.

How to Check Spark Plug Wires: A Step-by-Step Guide

Checking your spark plug wires regularly is essential for maintaining engine performance and preventing costly repairs. Follow the guide below to do the job successfully –

1. Visual Inspection of Spark Plug Wires

The first step in checking spark plug wires is to visually inspect them for any signs of wear, cracks, or damage. Over time, the heat and friction from the engine can cause the rubber insulation of the wires to crack, fray, or melt, which leads to engine misfires or weak sparks.

Here’s what to look for during a visual inspection:

- Cracks and Cuts: Look for any visible cracks, abrasions, or cuts along the length of the wire. These can expose the internal components of the wire, causing electrical leakage.

- Burn Marks: Overheating can cause burn marks on the insulation. This is a sign that the wire has been exposed to excessive heat, which could lead to failure.

- Wear at Connection Points: Check the connectors at both ends of the spark plug wire (at the spark plug and the ignition coil). The wire should be securely attached, and the connector should be clean and undamaged.

If any of the wires show visible damage, it’s time to replace them. Damaged wires can affect engine performance and cause misfires.

2. Checking for Spark Leakage

A common issue with spark plug wires is the leakage of high-voltage electricity. This can occur when the insulation around the wire is damaged or cracked. To check for spark leakage, you’ll need to perform the test in a dark environment to easily spot any arcs or sparks.

Steps:

- Start the Engine: With the hood open, start the engine and allow it to run at idle speed.

- Look for Sparks: Use a flashlight to inspect the spark plug wires. If you see visible electrical arcs or sparks jumping from the wire to nearby metal parts, it’s an indication that the wire is faulty.

- Check Multiple Wires: Inspect all wires, as electrical leakage can happen on any of them.

If spark leakage is visible, replace the faulty spark plug wire immediately. It’s crucial to address this issue quickly, as spark leakage can lead to misfires and decreased engine performance.

3. Testing Spark Plug Wires with a Multimeter

A digital multimeter is an essential tool for checking the condition of your spark plug wires. The multimeter will measure the resistance of the wire, which is an important factor in determining whether the wire is functioning properly.

Steps:

- Set the Multimeter: Set your digital multimeter to measure resistance in ohms.

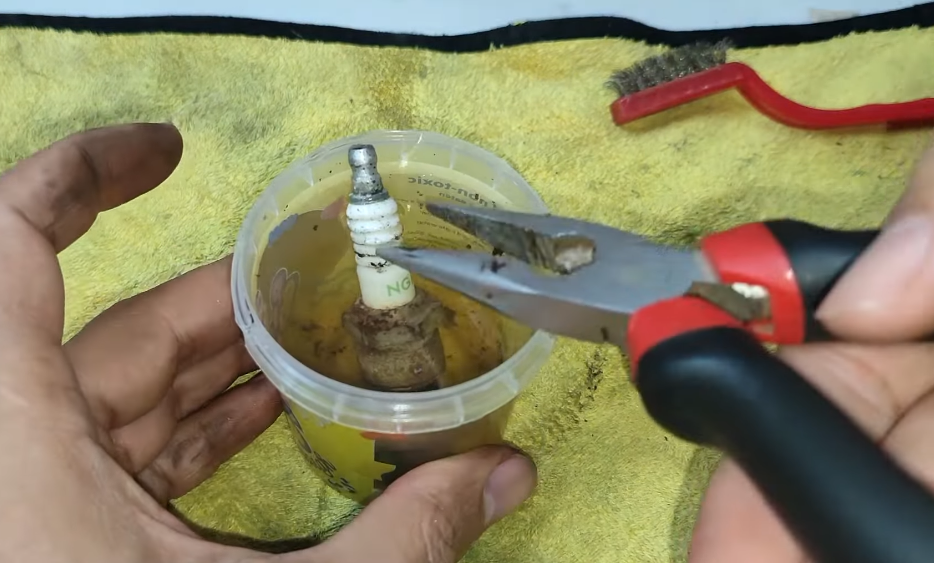

- Remove the Wire: Disconnect the spark plug wire from both the spark plug and the ignition coil.

- Measure the Resistance: Place one probe of the multimeter on the metal terminal at one end of the wire, and the other probe on the metal terminal at the opposite end.

- Check the Reading: The resistance should fall within the manufacturer’s specified range (typically between 3,000 and 7,000 ohms per meter for carbon core wires). If the resistance is too high or too low, it indicates that the wire is worn out and should be replaced.

Comparing the resistance reading to the manufacturer’s specifications is important. If it’s too high, the wire can no longer carry the necessary voltage, leading to engine misfires and poor fuel efficiency.

4. Spark Test with a Spark Tester

A spark tester is a useful tool to check the quality of the spark generated by the spark plug wire. A strong, consistent spark is necessary for the ignition process to work properly. A weak or inconsistent spark can indicate that the wire is not providing adequate voltage to the spark plug.

Steps:

- Remove the Spark Plug Wire: Disconnect the spark plug wire from the spark plug.

- Attach the Spark Tester: Connect a spark tester to the spark plug wire and ground the tester to a metal part of the engine.

- Crank the Engine: While the engine is cranking, observe the spark tester. A strong blue spark indicates that the wire is functioning correctly.

- Weak Spark: If the spark is weak or orange, it indicates that the wire is deteriorating and may need to be replaced.

Performing a spark test ensures that the wire is delivering a strong spark to the spark plug, which is essential for engine efficiency.

5. Wire Routing and Condition

The condition of the spark plug wires isn’t just about the wires themselves, but also about how they’re routed. If the wires are routed too close to hot components like the exhaust manifold or engine block, they can overheat and degrade quickly.

Here are some things to check:

- Proper Routing: Make sure the wires are routed away from hot engine components.

- Wiring Clips: Ensure that the wires are secured with clips to avoid excessive movement and rubbing against other parts.

- No Abrasions: Inspect the insulation to ensure that there are no abrasions caused by rubbing against other components.

If the wires are routed incorrectly or if they show signs of abrasion, reroute them carefully to prevent further damage.

6. Replace Faulty Spark Plug Wires

If any spark plug wires show damage, have high resistance, or fail the spark test, it’s time to replace them. Always replace all spark plug wires at once to ensure uniform performance across all cylinders. Using mismatched wires can cause uneven firing and reduce engine performance.

When purchasing new spark plug wires, make sure to choose the correct ones for your vehicle’s make and model. Consult the owner’s manual for the exact specifications.

Common Symptoms of Faulty Spark Plug Wires

Faulty spark plug wires can cause a range of engine problems, from misfires to poor acceleration. Recognizing these symptoms early can help prevent further damage to the vehicle’s ignition system.

- Engine Misfires: One of the most common symptoms of faulty spark plug wires is engine misfires. The engine may hesitate, stutter, or run unevenly, especially under load.

- Hard Starting: Worn-out wires can cause difficulty in starting the engine, especially in cold weather.

- Poor Acceleration: Faulty spark plug wires can lead to poor acceleration, as the engine is not firing properly.

- Check Engine Light: A malfunctioning spark plug wire can trigger the check engine light, especially if the wires are misfiring or losing connection.

- Rough Idle: The engine may idle roughly when the spark plug wires are not functioning properly.

When to Replace Spark Plug Wires

Spark plug wires should be replaced every 60,000 to 100,000 miles, depending on the type of wire (carbon core or copper) and the manufacturer’s recommendations. If you notice any of the symptoms above or if the wires fail the tests outlined in this guide, it’s time for a replacement.

Related Article

How Spark Plug Resistance Affects Spark

How to Replace Spark Plugs

Can Spark Plug Gap Cause Misfire?

What Spark Plug Brand Does Toyota Use?

Frequently Asked Questions

Here are some FAQs about check spark plug wires –

1. How can I tell if my spark plug wires are bad?

You can tell by inspecting the wires for visible damage, checking for spark leakage, testing the resistance with a multimeter, and performing a spark test.

2. What is the resistance of a good spark plug wire?

A good spark plug wire typically has a resistance between 3,000 and 7,000 ohms per meter for carbon core wires, though this may vary based on the manufacturer.

3. Can I test spark plug wires without removing them?

You can test for spark leakage by running the engine and looking for visible arcs or sparks, but to test the resistance, you’ll need to remove the wires.

4. What causes spark plug wires to go bad?

Over time, spark plug wires can wear out due to heat, vibration, exposure to engine fluids, or normal aging.

5. Should I replace all spark plug wires at once?

Yes, it’s generally a good idea to replace all the spark plug wires at once to ensure uniform performance and prevent uneven firing.

Conclusion

Regularly checking and maintaining the spark plug wires is essential for optimal engine performance. By following the steps outlined in this guide, you can easily identify worn or faulty wires and prevent engine misfires, poor fuel economy, and other related issues.