Do spark plugs need to be torqued? Yes, spark plugs should be torqued to the manufacturer’s recommended specification to ensure proper seating, heat transfer, and prevent damage to the engine or plug. Improper torque, whether too tight or too loose, can lead to engine misfires, poor performance, or long-term damage.

When people replace or install spark plugs in a vehicle, one of the most common things they wonder about is whether or not spark plugs need to be torqued, and if they do, then why. The spark plugs should be installed correctly as this is critical to the engine’s functioning, and an equally critical aspect is the amount of torque that is applied.

This is a comprehensive piece and we will be discussing the significance of torque with respect to spark plugs, how to apply it, and, most importantly, what happens when the right amount of torque is not applied.

Contents

- 1 What is Torque and Why Does It Matter for Spark Plugs?

- 2 Do Spark Plugs Need to be Torqued?

- 3 How do you determine the correct torque specification for a spark plug?

- 4 Why Is Proper Torque Important for Spark Plug Installation

- 5 How To Properly Torque Spark Plugs

- 6 What Happens If You Don’t Torque Spark Plugs Properly?

- 7 Frequently Asked Questions

- 8 Conclusion

What is Torque and Why Does It Matter for Spark Plugs?

Torque is the amount of force in the form of a rotational movement that is used in tightening parts. In this case, a spark plug. In the case of spark plugs, torque is important because it determines how well the plug is seated against the engine’s cylinder head and when you torque a spark plug properly, you achieve a number of important goals.

Proper Seal: Torque ensures that the spark plug’s threads and gasket make a proper seal against the cylinder head to make sure that no combustion gases escape, thus achieving optimal engine functioning, as well as efficient operation.

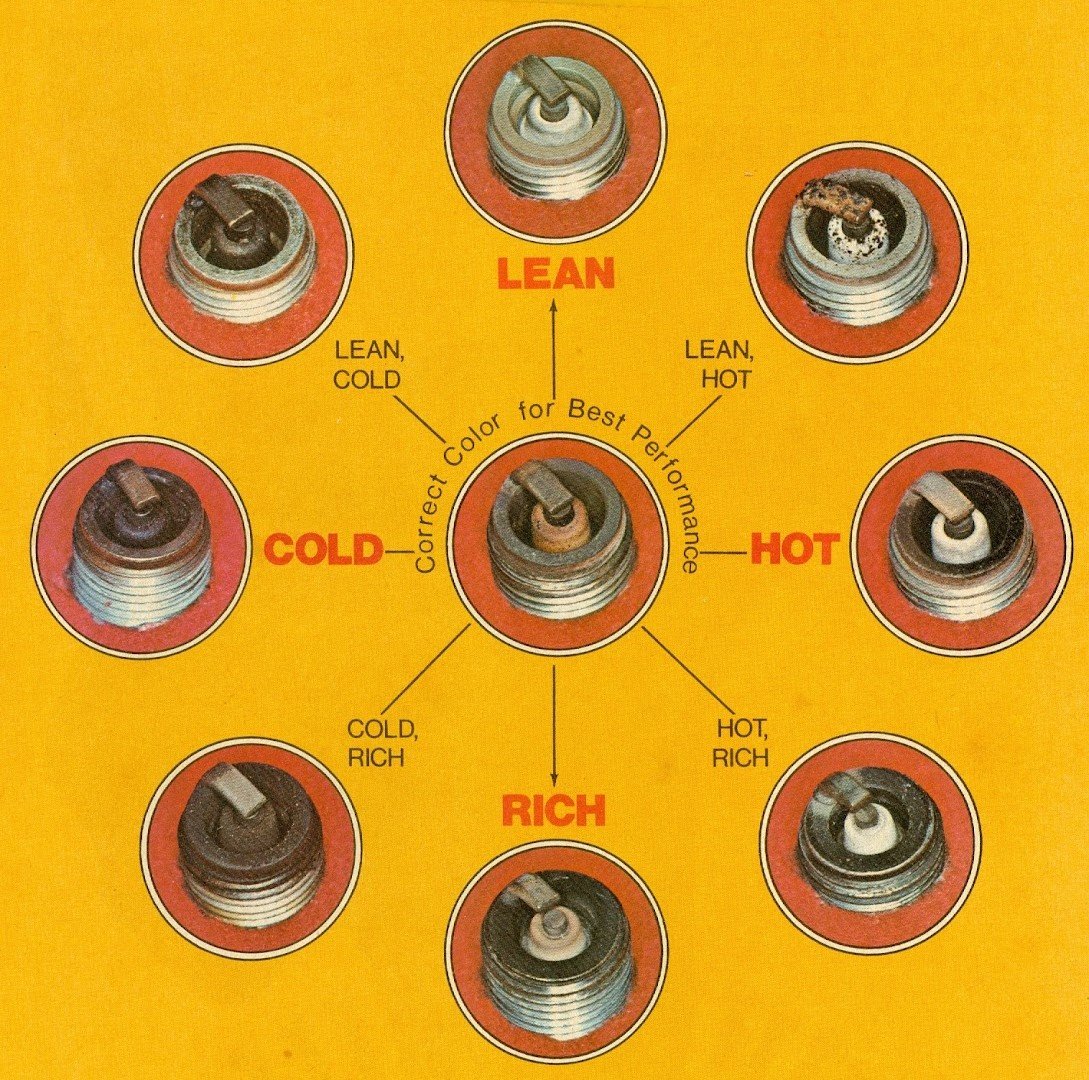

Proper Heat Transfer: Since spark plugs are in high temperature conditions, proper torque guarantees proper seating almost without gaps to ensure thorough transfer of heat from the spark plug to the cylinder head. Poor torque results in poor heat dissipation, ultimately leading to premature overheating and failure of the spark plug.

Preventing Damage: If a spark plug is not torqued to the correct spec, under and over torque in the slipstream case can at most times be very harmful. In this case, over torquing would strip the cylinder head threads and in the extreme, crack the spark plug. Under torquing would seat poorly and paired with the spark not being used, the seating would loosen over time making the performance worse.

Do Spark Plugs Need to be Torqued?

Yes, unfortunately spark plugs need to be torqued to the manufacturers recommendation. Spark plugs are not created under the same conditions, so factors such as cylinder head material and the country of origin can change the specification of the torque.

Some folks may ask: do I just keep twisting and tightening a spark plug until it just feels snug and, maybe, don’t even try to replace it? While it seems to be more convenient, it can cause issies later on. A spark plug that is too loose can’t create a proper seal while a spark plug that is overly tightened can damage the plug itself or the threads. Hence, the best practice is to find the recommended torque specification to the plug and use a torque wrench to fasten it.

How do you determine the correct torque specification for a spark plug?

The right torque specification for spark plugs have a few things to consider:

Spark plug size: Generally, the larger the spark plugs, the more torque it requires. 12 mm, 14 mm, and 18 mm plugs with thier respective torque value.

Cylinder head material: A softer material, such as an aluminum head, is more likely to become stripped and have threads cross with more torque as compared to a cast iron head.

Thread Types: Spark plugs can have different types of threads, such as tapered or flat seats. Generally, tapered plugs take less torque because they seal themselves, while flat plugs depend on a gasket and take more torque to seal.

Manufacturer Recommendations: Over tightening and under tightening should always be avoided, but more important is the manufacturer recommended torque specification. Each vehicle or engine has unique specifications we must follow.

Depending on the reasons above, airplane spark plugs generally range from 10 to 30 foot-pounds(lb-ft). Always follow the specifications provided in your airplane’s service manual or recommended instructions by the spark plug manufacturer.

Why Is Proper Torque Important for Spark Plug Installation

By properly torquing spark plugs, we can achieve the proper amount of seal and the needed heat transfer without damaging any of the components. Proper torque is equally important for other reasons as well:

Prevents Loosening: Spark plugs that have been under torqued over a period of time can cause misfiring, loss of fuel, and damage to the engine, especially the cylinder head. Loosening can also be a risk, and in the case where the spark plug becomes loose, it is very easy for it to fall off when the engine is running.

Lessens likelihood of damage: Damage can occur when a spark plug is fastened too tightly, snagging the threads on the spark plug or on the cylinder head. With aluminum heads, the threads can be stripped by the slightest torque, which can be a very costly repair. Over-tightening can also damage the spark plug by cracking the ceramic insulator, thus making it useless.

Enhances Performance: When spark plus are properly torqued, the connection becomes solid between the plug and the engine which is very important for it to be able to spark and combust. This makes the fuel more efficient, the engine more powerful, and operates more smoothly.

Dissipation of heat: The combustion process generates a lot of heat which can be poorly managed if the spark plug is loose or the wrong way. This however, also poses the risk of under-tightening the spark plug which can cause overheating and cause sp plug to wear. On the other hand, if the plug is deformed by too much torque, the heat will be poorly managed, causing it to loose the functionality of heating.

How To Properly Torque Spark Plugs

Be sure to follow the Installation and Service Manual for each cylinder of the engine regarding the torque the spark plugs need as it can be very different. It is also important to note however, to follow the stated steps:

Review the Torque Specification: As a general rule, always check to the service manual for the vehicle or the packaging the spark plugs came in for the right torque value. If you are still unsure, you can always ask someone more experienced than you regarding it or checking the specifications online is always a safe bet.

Use the Right Tools: A torque wrench is needed to check that the right amount of torque is done. A spark plug socket and an extension bar are useful for reaching plugs located in narrow spots.

Install the Spark Plugs by Hand: Carefully screw the spark plug into the cylinder head first. This way the spark plug gets aligned and prevents any cross threading.

Tighten Using a Torque Wrench: When the plug starts to be slightly more difficult to screw in by hand, a torque wrench is needed to tighten it to the right specification. Be careful to listen and see that the wrench does not surpass the set torque.

Double Check: Spark plugs need to be secure when dunking them into the wrench, however it seems fitting to mention that the adj and unscrew rule is also in play when doing so. If the torque wrench is not available, it is recommended to screw the plug on firmly, not too much though.

What Happens If You Don’t Torque Spark Plugs Properly?

If spark plugs are not set to the right torque, a variety of problem can be presented:

Engine Performance: For the spark engine to perform a start, its plugs must not be too loose and not too tightened to the right and can result in gaps. The inefficiency of an internal combustion engine at igniting the charge. Misfires, rough idle and inaccurate acceleration can also be a result.Engine Damage: Cross threading or over tightening can break or crack the spark plug and damage the threads on the cylinder head, resulting in expensive repairs.

Premature Spark Plug Failure: A spark plug which is not seated well can, due to the neoprene having no head as well as no cushion around it to absorb the heat, lead to their failinging prematurely.

Reduced Fuel Efficiency: The fuel in the tank boils off and thus increases the engine’s temp ment. A spark plug which is poorly working, does not create, or misfires, makes the engine burn more fuel. Then it has to compensate for the combustion which is due to the poor firing mechanics.

Frequently Asked Questions

Here are some FAQs on spark plugs need to be torque –

1. Should spark plugs be torqued every time they are replaced?

Yes, every time spark plugs are replaced, they should be torqued to manufacturer’s specifications to ensure they are properly replaced to avoid engine damage.

2. Can you put in spark plugs without a torque wrench?

Yes, you can put in spark plugs without a torque wrench, however, you are more likely to either under or over tighten it leading to engine or spark plug damage.

3. If I over tighten a spark plug, what happens?

If you over tighten a spark plug, the worst that can happen is that the threads of the cylinder head become damaged, the spark plug gets broken, or the shell of the plug gets deformed. If either of the mentioned happens, the engine will misfire and poor engine performance will be the result or even permanent damage to the engine itself.

4. How will I be able to tell if the spark plug has been properly torqued?

When the spark plug has been torqued to the engine specifications, there should be no more left or right movement. If the plug is loose, it is under torqued, and if it is too tight, then it has been over torqued.

5. Can spark plugs be reused after being torqued?

Sometimes plugs can be reused but it is critical to examine their condition. If plugs display electrodes on the verge of destruction, or if their disks look covered in a pumpkin, they qualify to be ditched. Before using another time, a zero check on the plugs is a must, form is needed, especially a gap in the disks.

Conclusion

To answer the primary question, do spark plugs need to be torqued? The answer is YES! Spark plugs should be torqued to avoid having to remove and re install the plug due to poor sealing, improper heat transfer and causing damage to the spark plugs and the engine. Always adhere to the manufacturer’s torque specs, proper tools should be used, and caution should be taken when installing.

Focusing more on the first step to make the engine work, torquing plugs properly will help improve the engine performance and avoid expensive repairs, as well as extend the lifespan of the plugs.

Proper torque should always be a priority regardless of whether the work is done professionally or by a DIY mechanic.