Dielectric grease on spark plugs prevents corrosion and moisture buildup, ensuring better conductivity and easier removal. It also protects the boot and terminal from heat and dirt.

When it comes to maintaining the vehicle’s ignition system, dielectric grease on spark plugs is often a recommended product, but how exactly does it work? Many car owners and mechanics use dielectric grease as a protective tool to ensure smooth engine performance, but its purpose and application can be a bit unclear.

In this blog post, we will explore what dielectric grease is, its role in the vehicle’s ignition system, and why it’s used on spark plugs.

Contents

What Is Dielectric Grease?

Dielectric grease is a silicone-based lubricant that is non-conductive, meaning it doesn’t allow electricity to flow through it. This makes it an ideal choice for use in electrical systems, including spark plugs, where you want to protect electrical connections but not interfere with the flow of current.

Why Use Dielectric Grease?

Dielectric grease serves as a protective barrier between electrical components. Its non-conductive nature ensures that it doesn’t affect the spark plug’s ability to generate the high-voltage spark needed for combustion. In fact, dielectric grease helps by improving the overall lifespan and efficiency of the spark plug, especially under harsh conditions.

Do You Need Dielectric Grease on Spark Plugs?

While it’s not always necessary, applying dielectric grease on spark plugs is a common practice in the automotive industry, particularly for vehicles in harsh environments. Let’s look at the reasons why you might consider using it.

1. Prevents Corrosion

One of the most significant benefits of using dielectric grease is its ability to prevent corrosion. Over time, exposure to moisture, heat, and chemicals can cause the electrical connections on the spark plug to corrode, affecting the performance of the spark plug and the engine as a whole. Dielectric grease helps by forming a protective seal that prevents moisture and dirt from entering the connection point.

2. Ensures Better Electrical Conductivity

While dielectric grease itself is non-conductive, it improves the electrical connection by reducing the chances of the spark plug boot getting stuck on the plug. This is especially helpful when you’re dealing with spark plugs in difficult-to-reach places or if the boots tend to get stuck after being removed. By making it easier to remove the spark plug boot, dielectric grease ensures that the connection remains intact and doesn’t cause electrical resistance.

3. Prevents Seizing or Sticking

Spark plug boots can become stuck to the spark plug due to heat and constant exposure to high-pressure engine conditions. The dielectric grease acts as a lubricant, reducing the chances of the boot becoming seized on the plug. This can save you a lot of frustration when performing maintenance or replacing spark plugs, especially when working in tight spaces.

How to Apply Dielectric Grease on Spark Plugs

Applying dielectric grease to spark plugs is a simple yet effective way to protect the electrical connections and ensure optimal engine performance. In this section, we’ll walk you through the steps to properly apply dielectric grease to spark plugs for maximum benefits.

Step-by-Step Guide to Applying Dielectric Grease

If you’ve decided to apply dielectric grease to your spark plugs, here’s a step-by-step guide on how to do it correctly:

- Gather Your Tools and Materials: You’ll need:

- Dielectric grease

- Spark plug socket

- Torque wrench (if needed)

- Clean rags

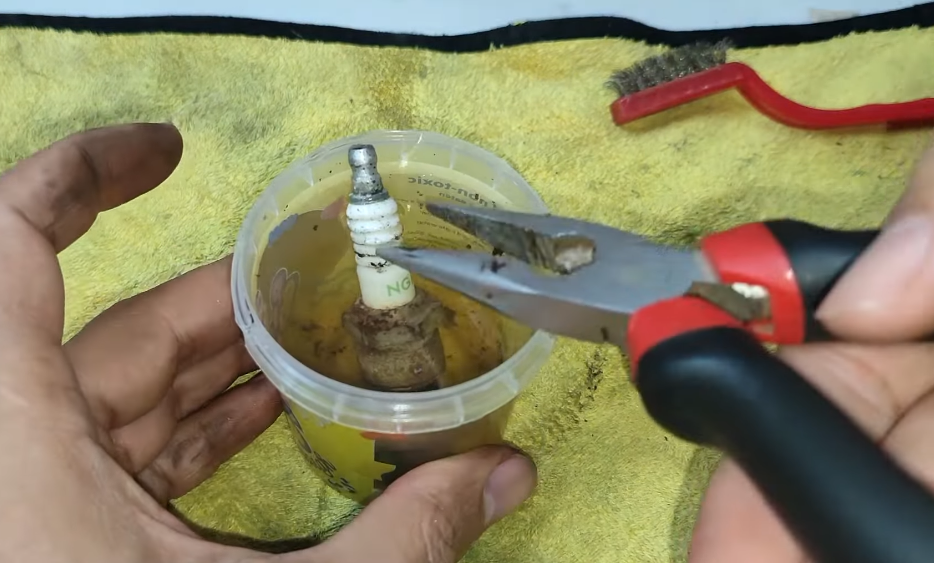

- Remove the Spark Plug Boots: Before applying the grease, remove the spark plug boots carefully. Inspect the boots for damage or wear before proceeding. If they are damaged, replace them before proceeding.

- Clean the Spark Plug: Clean the spark plug area thoroughly using a clean rag to remove dirt, oil, or debris that could prevent the grease from adhering properly.

- Apply the Dielectric Grease: Apply a small amount of dielectric grease to the inside of the spark plug boot, focusing on the area that comes into contact with the spark plug. You only need a small amount, as the grease is used to coat the surface and protect it, not to lubricate it heavily.

- Reattach the Spark Plug Boot: Once the dielectric grease is applied, reattach the spark plug boot to the spark plug. Be sure not to over-tighten, as this could cause damage to the boot or the spark plug.

- Inspect and Replace if Necessary: If you’re replacing the spark plugs, ensure that the new ones are also coated with dielectric grease before reinstallation. Once everything is in place, reconnect the spark plug wires, making sure everything is seated properly.

Benefits of Using Dielectric Grease on Spark Plugs

Dielectric grease offers several advantages when applied to spark plugs, from improving engine performance to preventing damage to spark plug connections. In this section, we will explore the key benefits of using dielectric grease on the vehicle’s spark plugs.

1. Improved Performance and Longevity

By preventing moisture and corrosion, dielectric grease helps to ensure that the spark plugs work more efficiently and last longer. This can improve the overall performance of the engine by maintaining a stable electrical connection and ensuring a smooth spark ignition.

2. Easier Maintenance

Using dielectric grease makes it easier to remove the spark plug boots during future maintenance. If the boots are frequently removed for inspections or replacements, the grease acts as a barrier, reducing wear and tear on the components. This also means less risk of damaging the boots when they are removed.

3. Prevents Grit and Dirt Buildup

Another benefit of dielectric grease is that it helps prevent dirt and other debris from accumulating on the spark plug connection. This is particularly important if you’re working in a dusty or dirty environment, as the grease helps keep contaminants away from the spark plug.

When NOT to Use Dielectric Grease on Spark Plugs

While dielectric grease is beneficial in many situations, there are instances when it may not be needed or even recommended. Here are a few scenarios to avoid using it:

- Not for the Spark Plug Itself: Dielectric grease should never be applied directly to the spark plug electrode. Doing so can prevent the spark from properly igniting the air-fuel mixture and damage the spark plug.

- Use with Caution in Some Performance Vehicles: For performance vehicles with specialized spark plugs or ignition systems, it’s essential to check the manufacturer’s guidelines before using dielectric grease, as it may interfere with the specific design of the ignition system.

Related Article

What Spark Plug Brand Does Toyota Use?

Why Do Some Engines Have 3 Spark Plugs Per Cylinder?

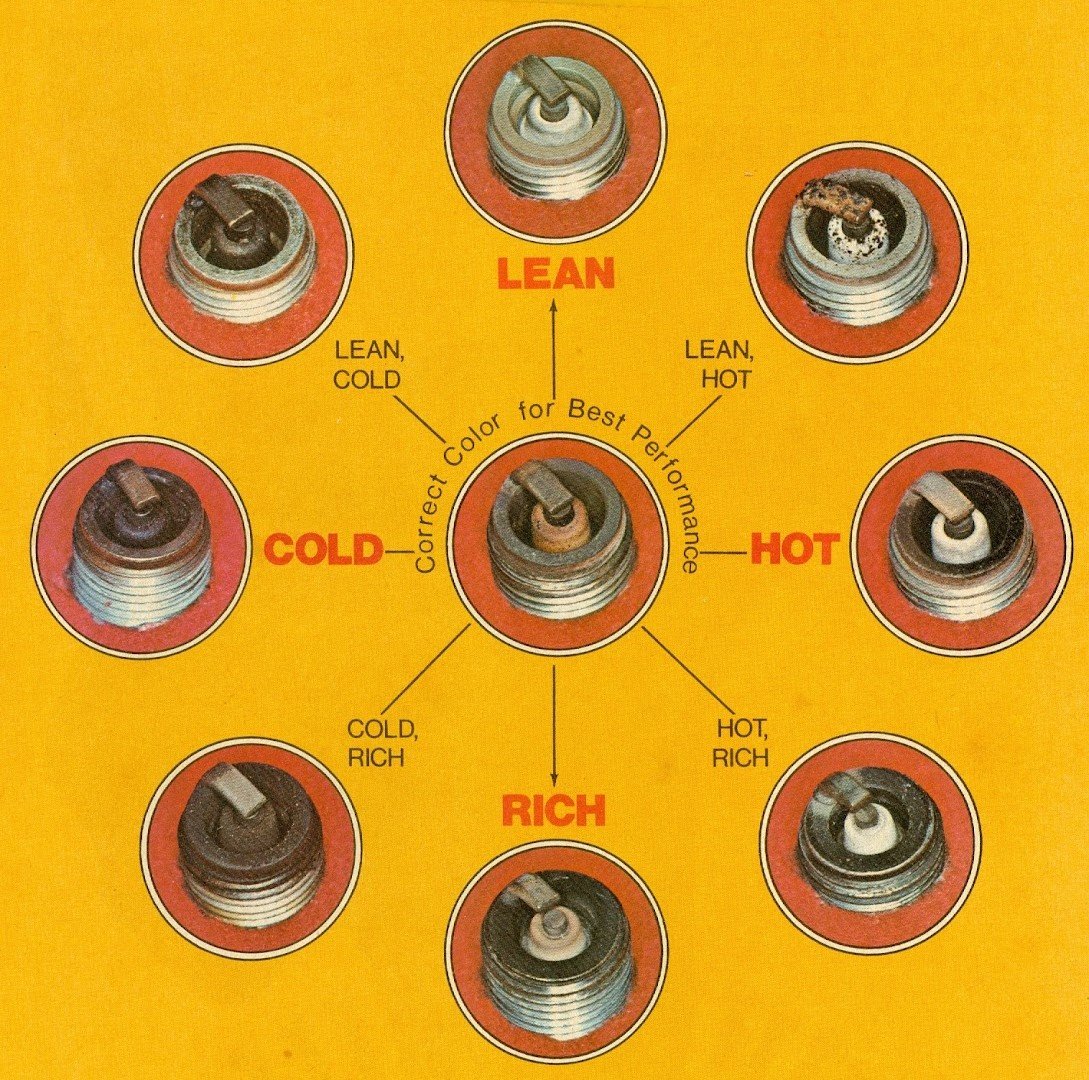

How to Read Spark Plugs

Frequently Asked Questions

Here are some FAQs about dielectric grease on spark plugs –

1. Can I use too much dielectric grease on spark plugs?

While dielectric grease is helpful, using too much can cause it to spread into places where it shouldn’t be, potentially affecting the spark plug connection. Always apply a thin layer, focusing on the boot area.

2. Does dielectric grease improve fuel efficiency?

By ensuring a better connection and preventing misfires, dielectric grease can indirectly contribute to better engine efficiency, though its effect on fuel efficiency is minimal compared to other factors like air filters or fuel injectors.

3. Should I apply dielectric grease to all spark plugs?

Yes, applying dielectric grease to all spark plugs can help ensure even performance and protection. It’s especially useful for vehicles in regions with harsh weather conditions.

4. Is dielectric grease the same as regular lubricant?

No, dielectric grease is specifically designed for electrical components, as it is non-conductive and doesn’t interfere with electrical connections. Regular lubricants may conduct electricity and should be avoided in these applications.

5. Can dielectric grease be used on spark plug wires?

Yes, dielectric grease can also be applied to spark plug wires where they connect to the spark plugs, helping to ensure a better seal and preventing moisture or dirt buildup.

Conclusion

Dielectric grease on spark plugs plays an important role in protecting the vehicle’s ignition system and ensuring smooth engine performance. While it may not be necessary for every vehicle, using dielectric grease on spark plugs can prevent corrosion, ensure better electrical conductivity, and reduce the likelihood of the spark plug boot getting stuck.

By following the proper application method, you can extend the life of the spark plugs and improve the vehicle’s overall performance. However, remember not to overapply the grease and avoid placing it on the spark plug electrode itself.