The Briggs and Stratton spark plug chart provides detailed information on the correct spark plugs for various engine models, including part numbers and gap sizes. By following this chart, you can ensure optimal engine performance and longevity by selecting the appropriate spark plug for your specific Briggs & Stratton engine.

One of the most important factors in the maintenance of your Briggs & Stratton engine is the spark plug which is usually overlooked. Small engines like lawn mowers, snow blowers, pressure washers, and generators work due to the spark plug which is often underestimated. In every engine, there is a combustion chamber that contains a mixture of fuel and air. The spark plug provides the spark that is needed to ignite the air-fuel mixture in the combustion chamber, thus starting the engine. If there were to be no spark, the engine would be rendered useless. Even in the cases where the engine is functioning, the operation would not be effective at all.

When it comes to your Briggs & Stratton engine, there are many factors to consider, including proper spark plug fitment, having your equipment operate smoothly, maximizing efficiency, throttle consumption, and equipment longevity. Using a damaged or incorrect spark plug can result in engine smoothies, poor performance and in bad cases, engine destruction.

Contents

Interpreting the Briggs & Stratton Spark Plug Chart

The Briggs & Stratton Spark Plug Chart is formulated to help customers find and chose the right engine specific spark plug. Different engines are designed to use different spark plugs for their size, shape, and use. Every Engine has its own unique features and the spark plug is one of its many components. This ensures the engine works to its fullest optimal capacity for as long as possible.

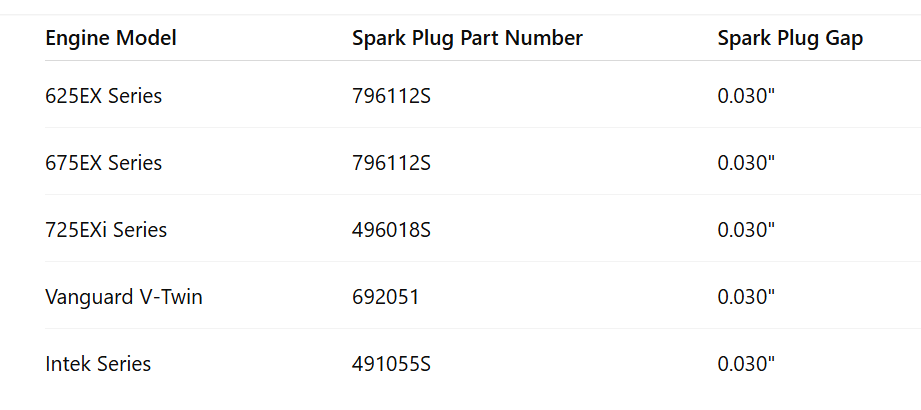

Spark Plug Chart for Common Briggs & Stratton Engine Models

Here’s a more detailed version of the spark plug chart, which highlights the part numbers and gap sizes for a variety of Briggs & Stratton engine models:

| Engine Model | Spark Plug Part Number | Spark Plug Gap |

|---|---|---|

| 625EX Series | 796112S | 0.030″ |

| 675EX Series | 796112S | 0.030″ |

| 725EXi Series | 496018S | 0.030″ |

| Vanguard V-Twin | 692051 | 0.030″ |

| Intek Series | 491055S | 0.030″ |

| 950 Series | 692051 | 0.030″ |

| Quantum Series | 495770 | 0.030″ |

| 550EX Series | 796112S | 0.030″ |

| 800 Series | 692051 | 0.030″ |

The Reasons Spark Plug Gaps Are Important

The distance of a spark plug’s center to its side electrodes is known as a spark plug gap and is very important in the functioning of the plug. Gaps that are too large or small can cause combustion inefficiency, as well as, overall destruction to the spark plug and the engine. Most Briggs & Stratton engines have a Spark Plug Gap of 0.030, but some may vary. Always check the manufacturer’s recommendations when setting the gap for your engine.

The Spark Plug Types Used In Briggs & Stratton Engines

Briggs & Stratton engines most commonly have four major types of spark plugs, and each varies for different engines and usages. Understanding the variations helps to equip you with the most appropriate spark plug.

1. Standard Resistor Plug

These are the most commonly used in Briggs & Stratton engines. Plug Standard Resistor is made to cut down the possibility of electronic interference to the engine’s other parts which ensures the effectiveness of sensitive electronics in the engine. They are the best plug option for basic lawnmowers, snow blowers, and other small engine gadgets.

Example: As customary, the sparkplug with part number 796112S, used in both the 625EX and 675EX series engines, is a standard resistor spark plug that focuses on reliability in ignition as well as performance.

2. Electromagnetic Suppression (EMS) Plugs

These plugs serve the distinct purpose of reducing Electromagnetic suppression plugs, designed to reduce EMI (Electromagnetic Interference). EMI is useful with respect to the engine noise and plug with the engine noise and plug with engine-driven generators. Wires that interconnect with sensitive electronic systems as engines equipped with Electronic Ignition Systems (EIS) or engines sensitive to engine, EMI suppression plugs are designed to. With them, the engine runs without disruptions or electrical interference.

3 .Extended Life Series Plugs

These plugs are designed to offer a longer than standard plugs. Extended life spark plugs is an advantage for engines that are worked on a lot, as they are designed to work for months after a single replacement.

Example: It is understood that an investment on a lawn mower or snowblower that is regularly used will pay off: in this case, the advantage is that the plugs can last more than twice the life of the standard plugs.

4. Platinum and Iridium Spark Plugs

High-performance spark plugs made of platinum and iridium have been noted as iridium and platinum spark plugs. These plugs sustain and give performance benefits because they have platinum and iridium materials for their electrodes. Platinum plugs last around twice as long as the standard plugs. Iridium plugs, on the other hand, can last up to four times what the standard plugs can last. In addition to this, these plugs improve fuel efficiency at the same time decreasing the emission of the chemicals as they give a more stable spark.

Example: These plugs boost performance and durability on Spark Plug Engines and the Vanguard V-Twin series. Engines performance also enhances at a high rate because of the 692051 platinum spark plug made for them.

Related Article

Which Spark Plug is Best Iridium or Platinum?

How to Choose the Right Spark Plug for the Engine

While it can be tempting to assume that picking the right spark plug for a Briggs & Stratton engine is overwhelming, it is the complete opposite if these steps are used.

Step 1. Find Your Engine Model

The first step is to identify the exact model of your Briggs & Stratton engine. Engine model can be found on the nameplate or the label. In finding the model, always include the type and the serial number as they can be vital in finding a spark plug that is compatible with your engine.

Step 2: Look at the Spark Plug Chart

After determining the spark plug for the engine model, it is appropriate to address the Briggs & Stratton Spark Plug Chart. In the chart, each engine model is paired with their suitable spark plug part number as well as the gap size. It is always best to use the spark plug the constructor recommends for the optimal functionalities.

Step 3: Disregard any Alternate Uses

The use to which an engine is put also affect which spark plug to use and how best to set it up. For an engine that is going to be used for commercial purposes and is going to be operated for long hours, then it is advisable to use the extended-life spark plugs. If the engine is driving an apparatus with delicate and sophisticated circuits, for example, a generator, then an electromagnetic suppression plug is preferable.

Maintenace Guidelines for Spark Plug

To keep an engine operating optimally, it is essential that the spark plug is properly maintained. The following points detail some necessary pieces of maintenance that need to followed.

Periodic Examination: The easiest way a user can keep up with maintenance is to set certain operational hours to be the intervals of maintenance checks. It is a good idea to inspect your spark plugs every 25 hours of operation or at the start of each season. Spark plugs can develop issues that stem from an excessive amount of time operating the apparatus. The most common of which being the performance issues because of a clog or a severe deposit.

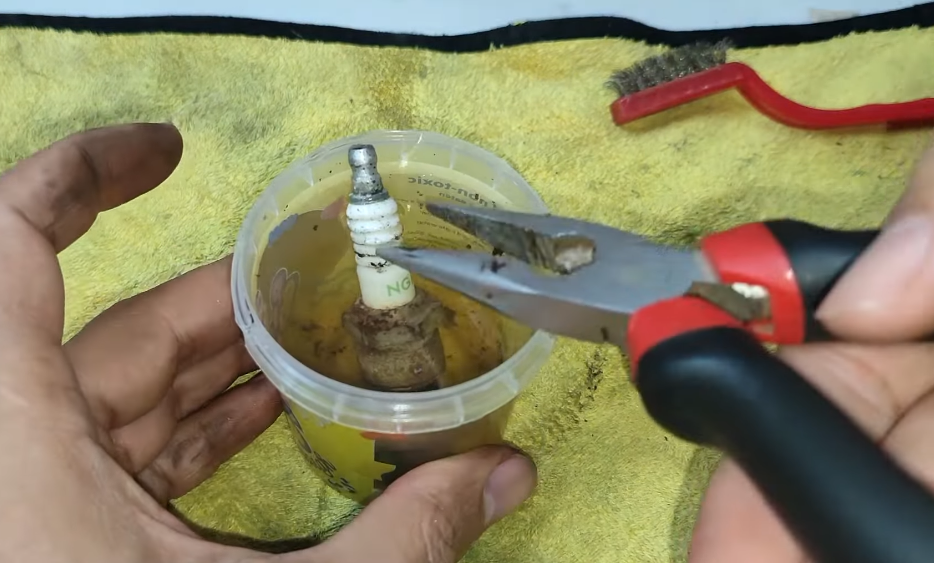

Cleaning the Spark Plug: If the regions of your spark plug are dirty but not worn out, you can extend its durability by cleaning it. Use a wire brush, or a spark plug cleaner, to erase the carbon deposits or grime. Make sure you do not harm the electrode or insulator during the cleaning process. If the spark plug starts showing any form of wear or corroded parts, switch it out without haste.

Replacing the Spark Plug: Even the best types of spark plugs have a life span. It is encouraged to discontinue use after a year or 100 hours of use, whichever comes first. If you notice any significant wear on the spark plug, such as a worn down electrode, you can switch it out sooner.

Setting the Proper Spark Plug Gap: The gap should always be set before putting a new spark plug in. Use a feeler gauge for best results. The more accurate the gap, the better the outcome. If a gap is not the correct distance between the center electrode and the side electrode it results in. It can cause misfires, poor fuel economy, and damage to the engine.

Troubleshooting Issues In Spark Plug Problems

There are several problems with spark plugs, and there are some solutions with which you can tackle them.

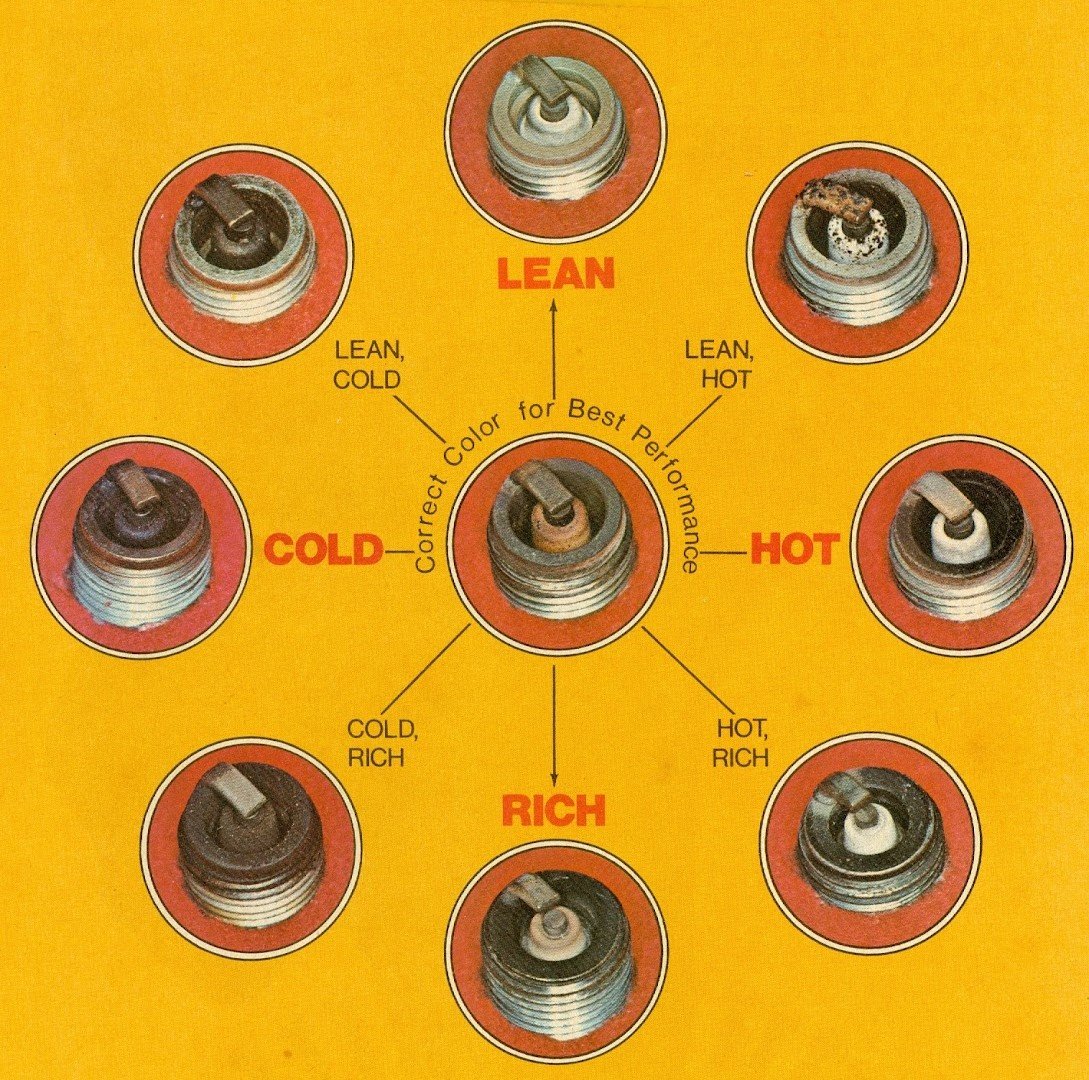

Hard Starting or No Start: If the engine has trouble starting, or worse, doesn’t start at all, the spark plug may be the trouble. Remove the spark plug and look at it. If there is any sight of it being worn out or is fouled. We call it fouled plug if the spark plug is covered with oil or has some carbon deposits on it, hence it not being able to spark. In this case the spark plug is fouled and needs to be cleaned or replaced.

Engine Misfire: If the engine misfire, there could be any number of reasons, one of which is the most frequent, the spark plug has not been gapped or damaged. Using feeler gauge check the gap and if it is reasonable. If the gap is too wide or too narrow, it will cause the engine to misfire. Also check the spark plug, it has not burnt or damaged.

Engine Performance Problems: A spark plug might be faulty if the engine either runs poorly or lacks power. Old or damaged spark plugs will fail to ignite the engine properly leading to sluggish performance. Replacing the spark plug is the logical solution, although you may want to consider other issues that might be present, such as clogged fuel lines and dirty air filters.

Frequently Asked Questions

Here are some FAQs on briggs and stratton spark plug chart –

1. What is the spark plug gap for a Briggs and Straton engine?

Most Briggs and Straton engines will have a spark plug gap of 0.030 inches. It is, however, best to check the owner’s manual of your engine to find out the correct gap size for your engine model.

2. Does the engine require any specific type of spark plugs?

Yes, the correct spark plug must be utilized for your engine model. Incorrectly using a spark plug for your engine can lead to the engine functioning poorly, damage to the engine, or in some cases, the engine won’t start at all.

3. How long is the average time interval before a spark plug must be replaced?

Usually, the recommendation is to replace the spark plug after 100 hours of use, or one year, whichever comes first. If the spark plug is worn out, for example, worn out electrodes, it is best to replace it before the year is over.

4. Is it possible to change the spark plug gap?

Yes, a spark plug gap can be adjusted, however, a feeler gauge or similar items must be used. Platinum or iridium plugs should be handled with care to avoid damage.

5. Where is the Briggs & Stratton Spark Plug Chart located?

The Spark Plug Chart can be accessed online, or it can be found in the engine manual with your equipment. Online resources such as MowersWeb and Inside The Yard also feature useful materials.

Conclusion

The efficiency and performance of your engine of your Briggs and Stratton equipment can be impacted. A lawnmower, a snowblower, or any other small engine will require the plug’s specifications to deliver optimal performance.

The maintenance practices outlined in this guide should be used in conjunction with the Spark Plug Chart. Doing so will ensure optimum performance and the ability to run your engine every year for many subsequent years.