Camshafts play a crucial role in determining the performance of an engine. They control the opening and closing of the valves, allowing air and fuel to enter the combustion chamber and exhaust gases to exit. To optimize performance, engine builders often use aftermarket components, such as rocker arms, to fine-tune the valve lift.

In this article, we will explore how to calculate cam lift with 1.7 rockers, providing you with a step-by-step guide and practical tips.

Contents

- 1 What are Cam Lift and Rockers?

- 2 What Are Rocker Arms?

- 3 Why Use 1.7 Ratio Rocker Arms?

- 4 Factors Affecting Cam Lift Calculation

- 5 Step-by-Step Guide to Calculating Cam Lift with 1.7 Rockers

- 6 Real-World Example: Calculating Cam Lift with 1.7 Rockers

- 7 Tips for Proper Cam Lift Calculation

- 8 FAQs: Answering Your Burning Questions

- 9 Conclusion

What are Cam Lift and Rockers?

The cam lift refers to the distance the camshaft lifts the valve off its seat during the valve opening event. It directly affects the amount of air and fuel that can flow into the combustion chamber. Rocker arms, on the other hand, are components that transfer the motion from the camshaft lobe to the valve. They act as a lever, amplifying the lift produced by the camshaft.

What Are Rocker Arms?

Rocker arms are critical components of an engine’s valve train system. They are typically mounted on a rocker shaft and pivot on a fulcrum. The pushrod connects the camshaft to the rocker arm, and the other end of the rocker arm contacts the valve stem. As the camshaft rotates, it pushes the pushrod, causing the rocker arm to pivot and open the valve.

Why Use 1.7 Ratio Rocker Arms?

Rocker arms come in various ratios, including 1.5, 1.6, and 1.7. The ratio represents the amount of valve lift achieved per unit of cam lift. For example, with a 1.7 rocker arm ratio, the valve will lift 1.7 times higher than the cam lobe lift. Using higher ratio rockers can increase valve lift, allowing more air and fuel into the combustion chamber, potentially enhancing performance.

Factors Affecting Cam Lift Calculation

Calculating cam lift involves considering several factors. Let’s explore them to understand the process better.

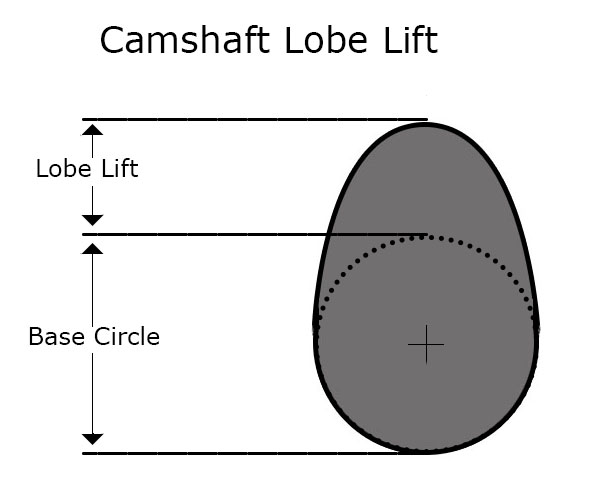

Base Circle Diameter: The base circle diameter is the lowest point on the cam lobe, where no lift occurs. It is essential to accurately measure this diameter as it serves as a reference point for calculating cam lift. You can measure the base circle diameter using a micrometer or by referring to the manufacturer’s specifications.

Valve Lift: Valve lift refers to the maximum distance the valve travels off its seat during the opening event. It is typically provided by the camshaft manufacturer or can be measured using a dial indicator. Accurate valve lift measurement is crucial for precise cam lift calculation.

Rocker Arm Ratio: The rocker arm ratio determines how much the valve lift is amplified compared to the cam lift. In this article, we will focus on calculating cam lift using 1.7 ratio rocker arms. The ratio is usually specified by the manufacturer or can be measured by dividing the valve lift by the cam lift.

Step-by-Step Guide to Calculating Cam Lift with 1.7 Rockers

Now, let’s dive into the step-by-step process of calculating cam lift using 1.7 ratio rockers.

Step 1: Determine the Base Circle Diameter: Start by measuring the base circle diameter of your camshaft. This can be done using a micrometer or by referring to the manufacturer’s specifications. Write down the measured value for future reference.

Step 2: Measure the Valve Lift: Using a dial indicator, measure the valve lift by placing the indicator on the valve retainer and slowly rotating the engine. Note down the maximum valve lift reading.

Step 3: Calculate Cam Lift: To calculate the cam lift, subtract the base circle diameter from the valve lift. This will give you the actual lift generated by the camshaft.

Step 4: Adjust for Rocker Arm Ratio: Since we are using 1.7 ratio rockers, multiply the calculated cam lift by 1.7 to obtain the effective valve lift. This accounts for the amplification provided by the rocker arms.

Real-World Example: Calculating Cam Lift with 1.7 Rockers

Let’s consider a practical example to illustrate the calculation process. Suppose the measured base circle diameter is 1.25 inches, and the valve lift is 0.5 inches.

Using the formula, the cam lift would be 0.5 inches (valve lift) – 1.25 inches (base circle diameter) = -0.75 inches.

However, the cam lift cannot be negative, so we consider it as 0 inches in this case.

Applying the rocker arm ratio of 1.7, the effective valve lift would be 0 inches (cam lift) x 1.7 (rocker arm ratio) = 0 inches.

Therefore, in this example, the calculated cam lift with 1.7 rockers is 0 inches.

Tips for Proper Cam Lift Calculation

To ensure accurate cam lift calculation and optimize engine performance, consider the following tips:

Accurate Measurements: Take precise measurements of the base circle diameter and valve lift to obtain reliable results. Use quality measuring tools and follow proper measurement techniques.

Consistency in Parts Selection: When selecting components for your engine, ensure compatibility and consistency. Use a camshaft, rocker arms, and other valve train components that are designed to work together effectively.

Seek Professional Assistance if Needed: If you are unsure about the cam lift calculation process or lack experience in engine building, it’s always recommended to consult a professional or an experienced engine builder. They can provide guidance and ensure accurate calculations.

FAQs: Answering Your Burning Questions

Q: Can I use different ratios of rocker arms?

A: Yes, rocker arms come in various ratios, such as 1.5, 1.6, and 1.7. The choice of rocker arm ratio depends on your specific engine requirements and performance goals.

Q: Are there any risks associated with incorrect cam lift calculation?

A: Incorrect cam lift calculation can lead to improper valve timing, reduced performance, or even engine damage. It’s crucial to follow the correct calculation process and seek professional advice if you’re unsure.

Q: Is cam lift the only factor to consider for engine performance?

A: No, a cam lift is just one of many factors that contribute to engine performance. Other factors include duration, overlap, valve size, combustion chamber design, and intake/exhaust system configuration.

Q: Can I calculate cam lift without using rocker arm ratios?

A: Rocker arm ratios are crucial for accurate cam lift calculations. Without considering the rocker arm ratio, you won’t have an accurate representation of the valve lift during engine operation.

Q: Can I use 1.7 rockers on a stock engine?

A: Using 1.7 rockers on a stock engine may not be recommended unless the engine has been specifically designed to accommodate the increased lift and duration provided by the rockers.

Q: Is it necessary to calculate the cam lift with 1.7 rockers?

A: Calculating a cam lift with 1.7 rockers is not mandatory, but it can provide valuable insights into the valve timing and help optimize engine performance.

Conclusion

Calculating cam lift with 1.7 rockers is a crucial step in optimizing engine performance. By understanding the relationship between camshafts and rockers, and following a step-by-step process, you can accurately determine the cam lift and achieve desired valve lift levels. Remember to take accurate measurements, select compatible components, and seek professional assistance if needed. With proper cam lift calculation, you can fine-tune your engine’s performance and achieve optimal results.